IOM-Ranger

5

FIGURE 3:

Insulated Body

Flangeless Design

NOTE:

The bon net

of in te gral ly flanged

bod ies should also not

be in su lat ed

SECTION IV

compliance with/to Spec. No. S-1134, the

valve is suitable for oxygen service. This

pro ce dure is limited to bodies of SST material

B. Trim

Removal:

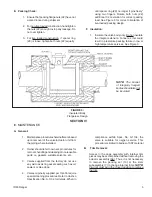

Access to the cage assembly with internal trim

pieces may be accomplished without removing the

actuator assembly (AA). Thus, it is not nec es sary

to remove the pack ing set (13) or the stem

subassembly (7) to change internal trims.

NOTE:

Plug (6) must be in the closed position to remove

the trim.

IV. MAINTENANCE

A. General:

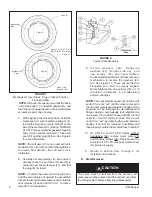

1. Maintenance procedures hereinafter are based

upon removal of the valve/actuator unit from

the piping where installed.

2. Owner should refer to owner’s procedures for

re mov al, handling and cleaning of non re us able

parts; i.e. gaskets, suitable solvents, etc.

3. Valves supplied from the factory do not use

any aid to assist in gasket sealing such as oil,

sealant or pipe dope.

4. Valves originally supplied per Opt-55 require

spe cial cleaning procedures. Refer to Cashco

Specification No. S-1134 for details. When in

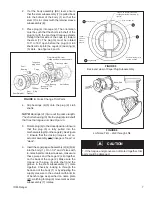

E. Packing

Check:

1. Ensure that packing flange nuts (22) have not

worked loose during shipment.

2. For non-live loaded construction, hand tight en

the nuts (22) enough to stop any leakage. Do

not over tighten.

3. For live loaded construction, if spacer ring

(29) is loose, tighten both nuts (22) equally

until spacer ring (29) no longer “spins freely”

using two fingers. Rotate both nuts (22)

ad di tion al 1/2 revolution for correct packing

load. See Figure 9 for correct orientation of

live-loaded packing design.

F.

Insulation:

1. Insulate the valve body only. Do not insulate

the integral extension bonnet as this could

result in premature packing failure in low or

high temperature services. See Fig ure 3.