IOM-Ranger

6

1. Position valve on a

fl

at work sur face with the

actuator assembly (AA) oriented vertical.

NOTE:

If actuator assembly (AA) has been

re moved, rotate stem (7) to close plug (6), and

proceed with Steps 4 through 8.

2. If the valve actuator includes a handwheel/

adjusting screw (58) assembly, use handwheel/

ad just ing screw (58) to remove the closing

torque; i.e. “stem windup”.

a. For ATO-FC valves: Loosen locking

le ver/nut (59) with CCW rotation when

viewed from above and rotate handwheel/

ad just ing screw (58) CW just enough to

relieve the closing torque, but not enough

to start opening the plug (approximately

1/2-1 handwheel rev o lu tion).

b. For ATC-FO valves: Loosen locking le ver

(59) with CCW rotation when viewed from

above and turn handwheel (58) CW to

fully close the plug (6) and then back

off enough to relieve the closing torque

by reversing the handwheel/adjusting

screw (58) CCW (approximately 1/2-1

handwheel revolution).

c. Remove machine screws (36) and

cover plate (20). Through opening in

arm hous ing (4), insert a tool similar to a

screw driv er and apply force to either side

at the lower rod end (9). Rod end (9) will

move easily from side to side when all

clos ing torque has been relieved.

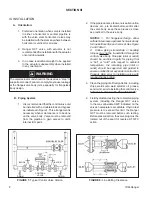

3. If the valve actuator does not include

handwheel (58) assembly, connect a

tem po rary air supply with an in-line ad just able

airset reg u la tor with gauge to the ac tu a tor top

works. Remove machine screws (36) and

cover plate (20).

a. For ATC-FO Valves: Pressurize ac tu a tor

to a level 2-3 psig (0.1-0.2 Barg) under the

upper pressure lev el of the bench setting

as stated on the name plate (21); i.e. 5-15

psig (.34–1.03 Barg) range, set pressure

at 12-13 psig (.83-.90 Barg). Refer to 2.c.

previous to con

fi

rm relief of all closing

torque. Ad just ac tu a tor pres sure slow ly

±1 to 2 psig (±.07–0.2 Barg) to con

fi

rm

great est/eas i est move ment of lower rod

end (9).

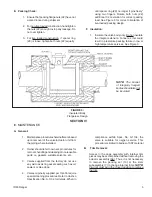

4. Remove the seal retainer screws (18) and

washers (23) and (47)

5. Remove the seal retainer (3) (full or i

fi

ce,

re duced, anti-cavitation, lo-noise), seal re tain er

gas ket (9), soft seal (10) (if supplied) and metal

seal (11).

6. Through backside of body (1), place a wood en

hammer handle on the vane on the back side

of the plug (6), or the LN2–LN4 lo-noise insert

(25), and tap lightly to remove cage as sem bly.

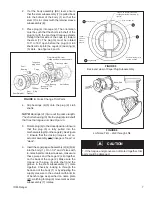

7. Remove bearings (4)( 5) from the cage (2).

(If necessary, pry or tap the bear ings loose.)

Rotate plug (6) 135° to 180° from the closed

position and lift plug (6) from the cage (2).

8. Remove abrasion sleeve (26) or LN2–LN4

lo-noise insert, if installed.

9. Depressurize actuator for ATC-FO valves.

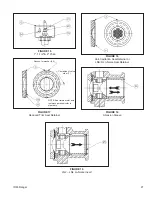

C. Trim

Reassembly:

Inspect and clean all parts. If any parts are worn,

replace with new parts. If the stem assembly (7)

has been removed, reassemble per Section IV,

Sub sec tion F., then proceed to reassemble the trim.

For sizes 1" - 3", Reorient unit so that the back-end

of the body (1) is directed downwards, and the

front-end is up wards and in a horizontal plane. In

this position gravity will assist in proper alignment of

internals. For 4" - 8" sizes orient body on its side.

NOTES:

A. The seal retainer gasket (9) and soft

seal (10) should always be replaced after every

dis as sem bly. Use only original factory re place ment

parts.

B. For ATC-FO Valves without handwheel

(58) assembly: Pressurize ac tu a tor to levels

in di cat ed per previous Sub sec tion 3.a. to prop er ly

align groove in stem sub as sem bly (7) to mate with

the tongue on the plug (6).

1. Install LN2/4 “lo-noise” insert (25) or “abra sion

sleeve” insert (26) into the body (1) cavity before

inserting the cage/plug subassembly (2)(4)(5)

(6). Ensure that the insert (25)(26) is properly

located within the groove located in the back-

end of the body (1)

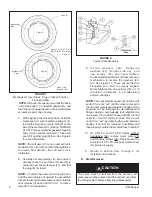

NOTE:

For proper orientation of LN2, LN3 or LN4

trims, see Figure 6.

WARNING

Do not insert hands/

fi

ngers into body (1) or actuator

arm housing (4) openings while actuator is pressurized.