IOM-Ranger

7

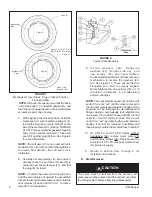

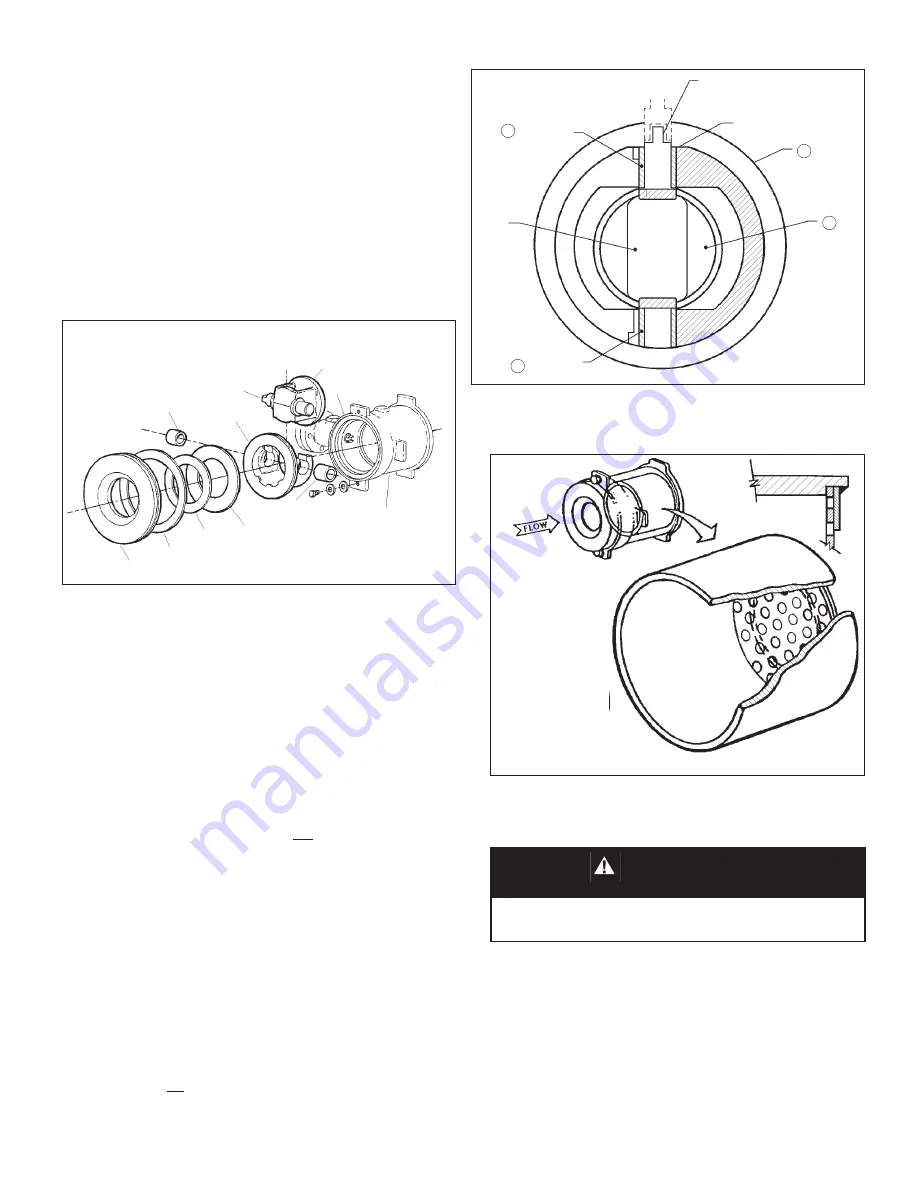

5 Short Bearing

4 Long Bearing

2

6

“Tongue” on plug (6) stub shaft,

to engage with stem assembly (7)

“groove”.

“Flat” on cage (2)

“Vane”

on back

side of

plug (6)

Shown with plug (6) in

“closed” position

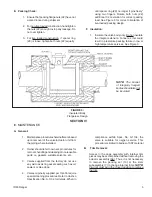

FIGURE 5

Back-end view of Cage/Plug Subassembly

Back-End

LN1 Trim

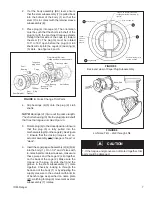

FIGURE 6

Lo-Noise Trim – LN2 through LN4

CAUTION

1. If the tongue and groove are not mated together, trim

parts could be damaged.

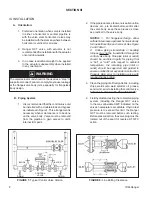

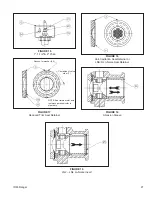

FIGURE 4:

Quick Change Trim Parts

Seal

Gasket

TFE Seal

Ring

Cage

Tongue on

plug shaft

Groove on stem

Valve Body

Inconel X-750

Seal Ring

Plug rotated 180° from

closed position for dis as sem bly

Short

Bearing

Seat Retainer

Long Bearing

4. Slip bearings (4)(5) onto the plug (6) stub

shafts.

NOTE:

Bearings (4) (5) are not the same length.

The shorter bear ing (5) fits the plug (6) stub shaft

that has the tongue end. See Figure 5.

5. Rotate plug (6) to the closed position. Ensure

that the plug (6) is fully pulled into the

me chan i cal stop (5) on the cage (2). See Figure

7. Ensure that the closing torque is nil; i.e.

actuator assembly (AA) linkage is “loose” or

“slack”.

6. Insert the cage/plug subassembly (2)(4)(5)(6)

into the body (1). On 1-1/2" and 2" sizes with

lo-noise inserts or abra sion sleeve, make sure

these pieces and the cage (2) slip together

on the back of the cage (2). Make sure the

tongue on the plug (6) stub shaft and the

groove in the stem sub as sem bly (7) mate

to geth er. Check by look ing in through the

back-end of the body (1) or by ad just ing the

supply pres sure to the ac tu a tor within limits

of bench range as spec i fied on name plate

(21), watch ing for plug (6) move ment as stem

sub as sem bly (7) ro tates.

2. If at the body assembly (BA) level, ensure

that the stem sub as sem bly (7) is pulled back

into the bonnet of the body (1) so that the

stem (7) is in contact with the retainer sleeve

sub as sem bly (8).

3. Place plug (6) into cage (2). The ori en ta tion

must be such that the short stub shaft of the

plug (6) with the ma chined tongue extends

through the flat side of the cage (2) toward

the stem (7). The plug (6) must be rotated

135° to 180° open before the plug (6) stub

shafts will slip into the cage's (2) bearing (4)

(5) slots. See figures 4 and 5.