IOM-Ranger

8

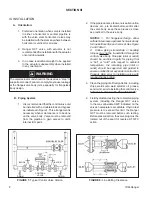

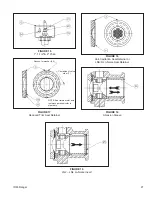

FIGURE 7

Mechanical Travel Stops - Plug in Closed Position

Front-End View

Mechanical

Stop

Cage (2)

Mechanical

Stops

Cage (2)

Sizes 2" & 4"

(DN50 & 100)

Plug (6)

Plug (6)

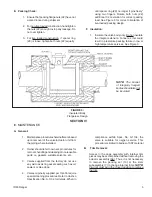

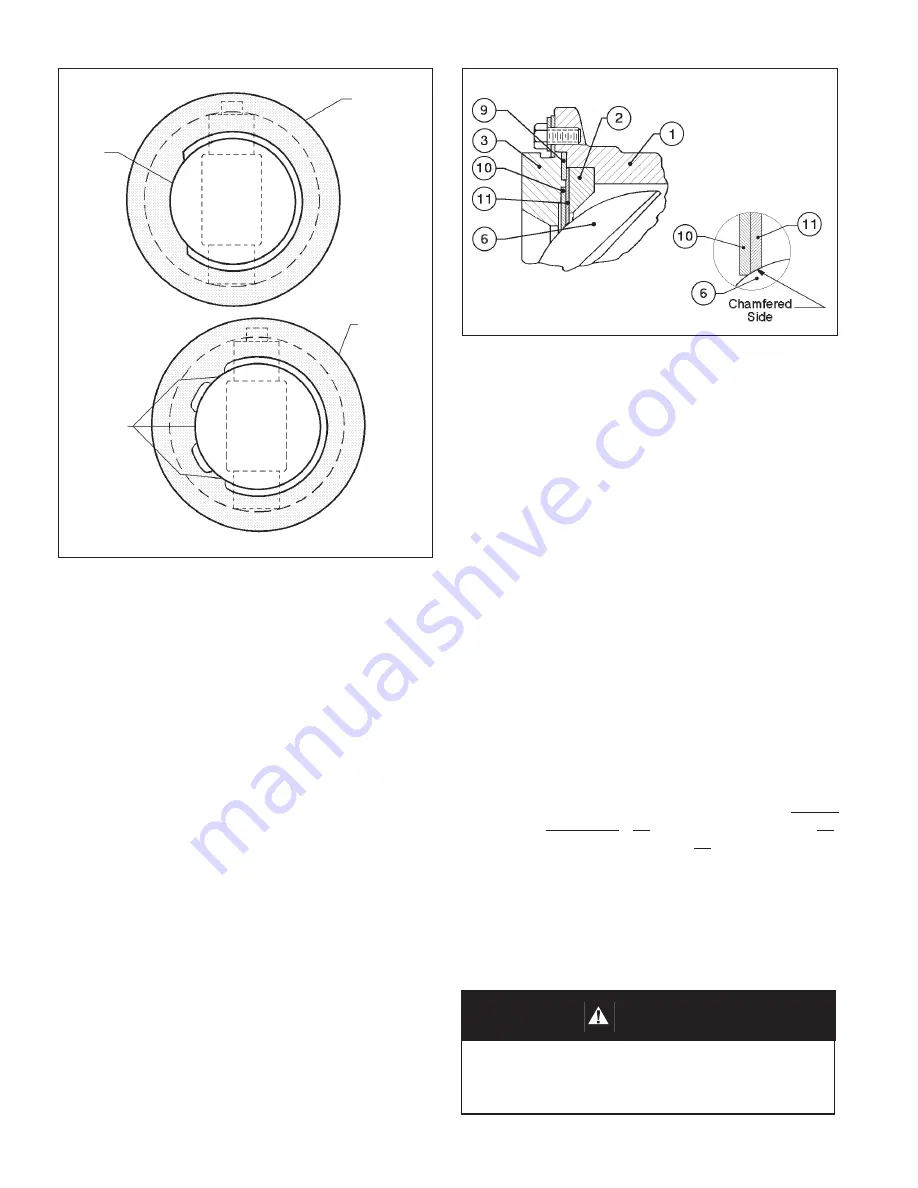

FIGURE 8:

Typical Seal Assembly

Sizes 1", 1-1/2", 3", 6" & 8"

(DN25, 40, 80, 150 & 200)

CAUTION

The valve must be isolated from the process, all

pres sures must be relieved and the unit removed from

the piping system before attempting disassembly.

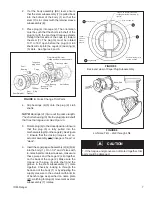

9. I n s t a l l w a s h e r s ( 2 3 ) , B e l l e v i l l e

washers (47) (convex side up) and

cap screws (18) and hand tighten.

Reduced port seal re tain ers (3) have re cess es

ma chined-in to receive the washers (23,

47). See Figure 17. These ensure that the

elon gat ed port (slot) is prop er ly aligned.

Wrench-tighten the cap screws (18) in 1/2

revolution in cre ments, in an alternating

pat tern, until tight.

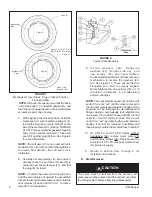

NOTE:

The seal retainer gasket (9) and the soft

seal (10) are not “set” until the valve is placed in

the line and compressed between flanges. If the

seals are “set” by clamping the valve between the

flang es during a seat leak age test, retighten the

cap screws (18) to hold the seal retainer (3) and

seals (9, 10 and 11) firmly in place. Once a soft

seal (10) is “set” by clamping the valve be tween

flanges, it cannot be re moved, re in stalled and

then prop er ly centered to pro vide Class VI shutoff.

10. On ATO-FC and ATC-FO Valves with out

handwheel (58), replace cover plate (20)

and machine screws (36). De pres sur ize the

ac tu a tor for ATC-FO valves and dis con nect

tem po rary air sup ply.

11. Return to Section III.A. through F. for

in stal la tion instructions.

NOTE:

All Sizes - Reorient unit so that the back-

end of the body (1) is directed downwards, and

the front-end is up wards and in a horizontal plane

so seals properly align on plug.

7. With plug (6) in the closed position, install the

metal seal (11) with cham fered edge of I.D.

to ward the plug (6); a note is “etched” on the

side of the metal seal (11) stating “TO WARD

PLUG”. Place seal re tain er gas ket (9) against

body (1) face and metal seal (11). Place soft

seal (10) against plug (6) face. See Figure 8

for as sem bly details.

NOTE:

The soft seal (10) is not used with anti-

cavitation trim (3) or with some trim des ig na tions.

In reverse flow di rec tion, the soft seal (10) is

ineffective.

8. Carefully set seal retainer (3) into position.

Vi su al ly check to see if the soft seal (10) is

centered over the metal seal (11), and that

the plug (6) is closed.

NOTE:

To center the seals on the plug (6) face,

hold the seal retainer (3) against the as sem bled

trim parts with light hand pressure and rotate the

seal retainer (3) back and forth 90°, 3-4 times.

Spin 360° 3-4 revolutions.

D.

Stem

Removal: