IOM-Ranger

9

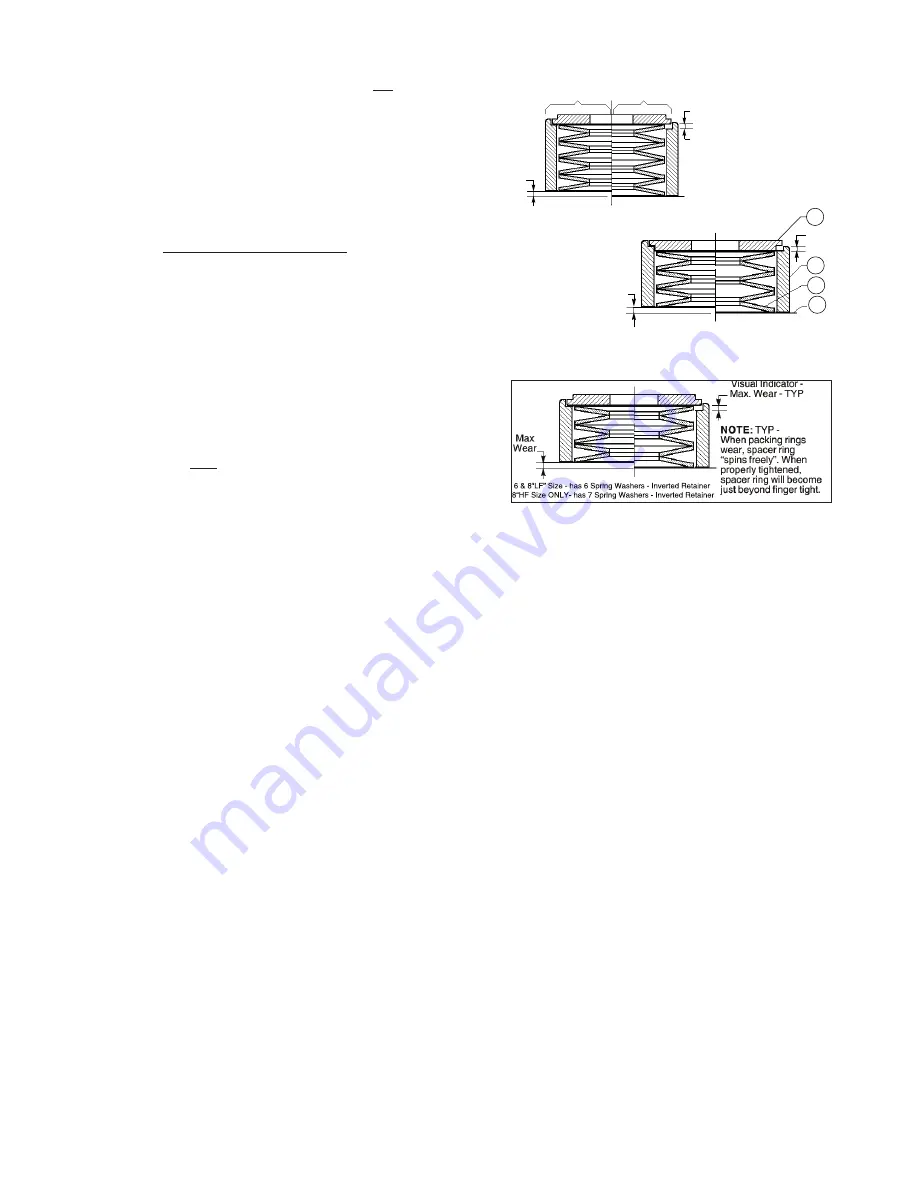

Max Wear

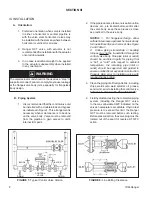

Max

Wear

29

28

2

1

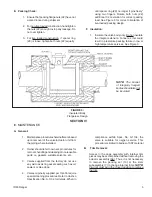

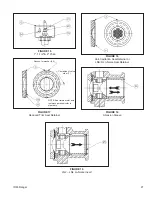

2", 3" & 4" RANGERS ONLY

6 Spring Washers

Non-Inverted Retainer

FIGURE 9

Ranger Live-Loaded Packing Design

Initial Setting

Position - TYP

Maximum Wear Position

-Adjustment Required - TYP

Max Wear

0.050"-0.060"

- TYP

Max

Wear

1" & 1-1/2" RANGERS ONLY

8 Spring Washers - Inverted Retainer

i.

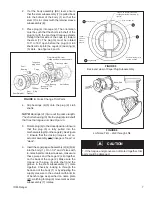

Pull yoke (12), packing flange (14), pack ing

follower (15) and follower bushing strip

(16) off over end of stem (7). Re place

packing follower (15) if sig nif i cant ly

cor rod ed. Always replace fol low er

bushing strip (16) when of standard

construction.

(NOTE:

When Opt-38HT

high tem per a ture pack ing is sup plied,

the packing fol low er (15.1) con tains a

pressed-in car bon bush ing (15.2) that is

not field re place able and must be sup plied

as a packing follower (15) sub as sem bly.)

j. Loosen stem retainer screw (17) by

ro tat ing CCW (viewed from above screw

head) 2-3 rev o lu tions to check for trapped

fluid. After all fluid is vented, remove screw

(17).

k. Rotate stem (7) CW when viewed from

actuator end of stem (7) to close plug (6).

l. Withdraw stem subassembly (7), retainer

sleeve subassembly (8) and packing set

(13) out of body (1).

NOTE:

If difficulty is encountered in re mov ing

the stem subassembly (7), use a puller

as sem bly. See Figure 10. Hold the double nut

with a wrench to prevent rotation of the stem

as this could damage the seals if the trim is

still in the valve body (1). Use the single nut

to jack the stem sub as sem bly (7) out.

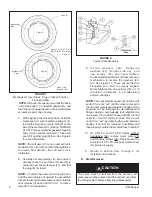

1. Remove the actuator as sem bly (AA) from the

valve body as sem bly (BA). Refer to Ac tu a tor

main te nance manuals IOM-48 or 148.

2. Secure body (1) in a vise with the stem (7)

hor i zon tal to the floor. Place matchmarks

be tween yoke (12) and body (1) to assist in

final orientation when re-assembled.

3. For live-loaded construction:

a. Loosen both packing flange nuts (22) until

clearance exists between the bot tom of

the nut (22) and the retainer (28).

b. Spacer ring (29) should “spin freely”. If

stacked mech a nism (27)(28)(29) is not

loose due to corrosion, debris, packed

dirt, etc., tap the spacer ring (29) lightly

while at tempt ing to pry up the spacer ring

(29) bottom with a thin flat tool.

c. Remove both packing flange nuts (22)

only after the live-loaded mechanism (27)

(28)(29) is “free” and loose.

d. Pry up both live-loaded mechanisms (27)

(28)(29) one side at a time. Carefully lift the

mechanism (27)(28)(29) over the pack ing

stud (21) ensuring that the Belleville spring

washers (27) are not dropped in removal,

preventing a de ter mi na tion of washers'

(27) orientation one-to-the-oth er. Set

the two mech a nisms (27)(28)(29) down

together, side by side.

e. Inspect the retainers (28) for ori en ta tion.

Both of the retainers (28) should have

the same orientation. Improper/differing

ori en ta tions will cause un bal anced

loading of the packing rings (13). See

Figure 9 for proper ori en ta tion.

f. Inspect both spring washer (27) stacks

for proper orientation by carefully lifting

off the spacer ring (29) and retainer (28),

exposing the spring washer (27) stack.

Each stack of spring washers (27) should

be oriented the same. Improper/differing

orientation will cause unbalanced load ing

of the packing rings (13). See Figure 9

for proper orientation.

g. Replace all Belleville spring wash ers

(27) if there are any signs of corrosion.

It is recommended that spring washers

be replaced in full sets. The spacer rings

(29), retainers (28), as well as the packing

studs (21) should be re placed if corroded.

h. Remove yoke (12) bolting by removing

two cap screws (19) on 1", 1-1/2" and 2"

sizes, or two nuts (22) on the 3", 4", 6"

and 8" sizes.