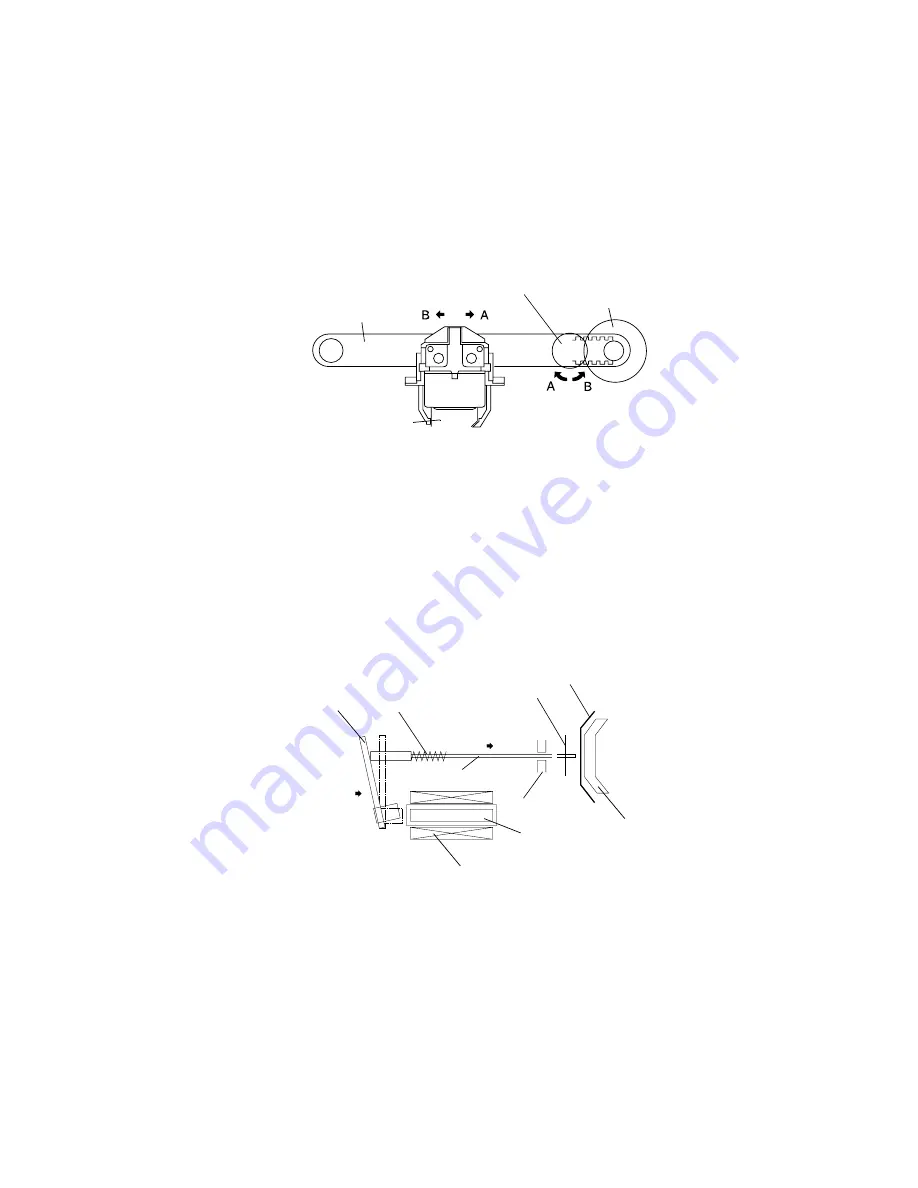

Print head unit movement

When the carriage motor is driven and the carriage motor gear moves in the direction of arrow B

(forward rotation), the rotational power is conveyed to the belt drive pulley, then the belt. Next,

the carriage sub assembly, which is fixed to the belt, moves in the direction of arrow B.

When the carriage motor gear rotates in the direction of arrow A (reverse rotation), the carriage

sub assembly moves in the direction of arrow A.

Wire movement when a single dot is printed

When the specified print head drive pulse is input to the drive coil, the iron core is magnetized,

and the actuating plate is pulled in the direction of arrow A. This action pushes the wire toward

the platen. When the wire strikes the ink ribbon and paper against the platen, a single dot is

printed. (The “platen” is the portion of the paper feed frame being struck by the wires during

printing.)

When energizing of the drive coil is completed, the wire and actuating plate are returned to the

standby position by the wire return spring and actuating plate spring.

Figure 2-3 Print head unit movement

Figure 2-4 Printing

Belt

Carriage motor gear

Belt drive pulley

Carriage sub assembly

B

A

Actuating

Paper roll

Ink ribbon

Wire return

Drive coil

plate

spring

Wire

Wire guide

Iron core

Platen

— 28 —

Summary of Contents for UP-250

Page 1: ...EXTERNAL PRINTER FEB 2000 MODEL UP 250 without price TECHNICAL MANUAL ...

Page 95: ... 86 END END Yes No Action 4 Replace main PCB Replace printer OK Action 4 mechanism assembly ...

Page 136: ... 127 ...

Page 149: ... 140 Main Circuit Board Parts Layout ...

Page 150: ... 141 RS 232 Serial Interface Circuit Board Parts Layout ...

Page 151: ... 142 IEEE 1284 Parallel Interface Circuit Board Parts Layout ...

Page 152: ...RS 485 Serial Interface Circuit Board Parts Layout 143 ...

Page 160: ... 151 Case Unit Lubrication Points Diagram 4 G 31 4 G 31 3 G 31 3 G 31 ...

Page 163: ... 154 EXPLODED DIAGRAM FOR TM U200B U210B NO 1 ...

Page 164: ... 155 EXPLODED DIAGRAM FOR TM U200B U200PB U210B U210PB NO 2 ...