—

— 81

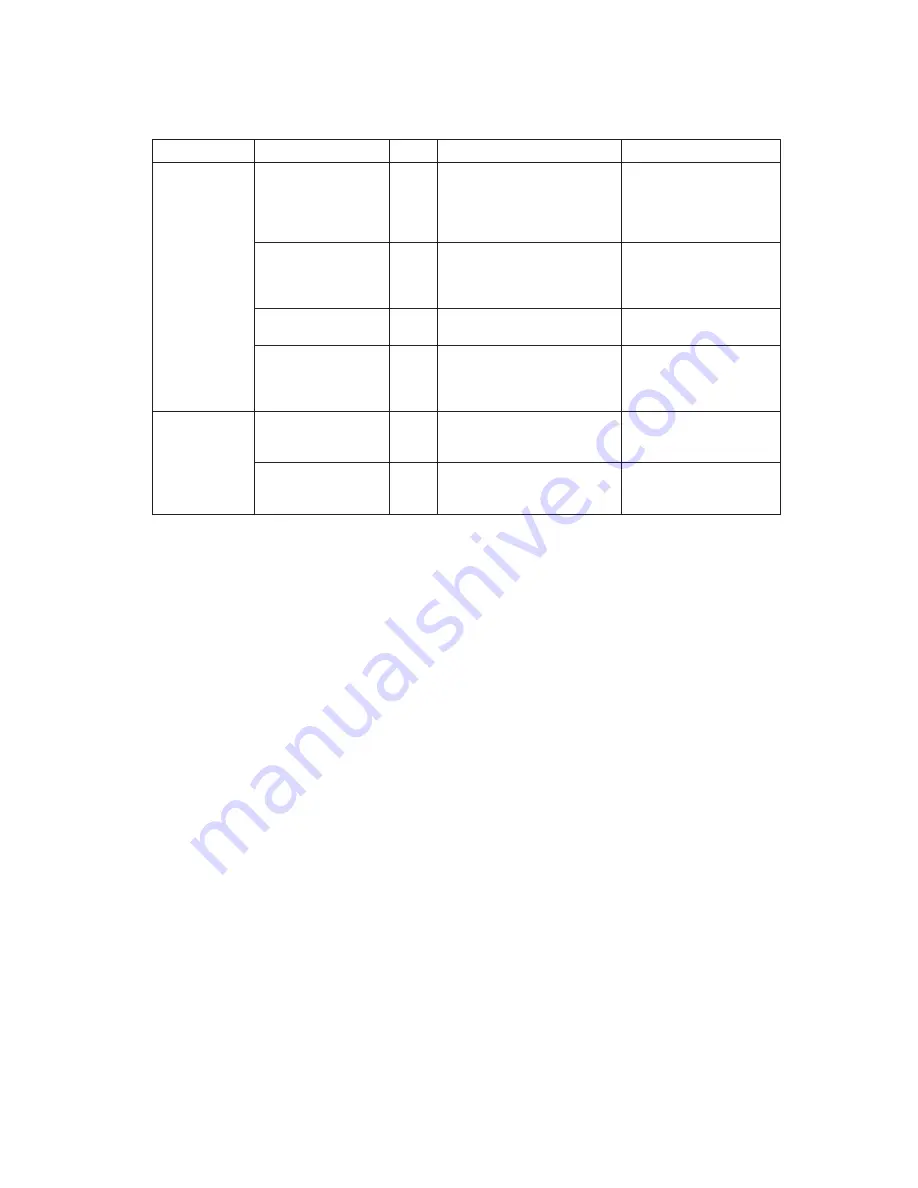

The print color

is mixed. (Half

of the character

is black and the

other half is

red.)

The ribbon cassette

is floating.

Verify that the ribbon cassette

is mounted correctly.

Mount the ribbon cassette

in the correct position.

(See “Replacing the

Ribbon Cassette” in

Chapter 3.)

The ribbon is placed

incorrectly.

Verify that the ribbon is not

placed between the print

head mask assembly and

paper feed frame assembly.

Place the ribbon between

the print head unit and

print head mask

assembly.

The ribbon frame

assembly is deformed.

Verify that the ribbon frame

assembly is not deformed.

If deformed, replace the

ribbon frame assembly.

The ribbon is

defective.

Verify that the color of the

ribbon is not blurred, or the

ribbon is not rumpled or

worm

Replace the ribbon

cassette if the ribbon is

worn or the print color is

light.

Color does not

change. (Black

to red or red to

black.)

The ribbon release

spring is unhooked

or damaged.

Verify that the ribbon release

spring is not unhooked or

damaged.

If the spring is unhooked,

hook it back on. If it is

damaged, replace it.

The ribbon frame

spring is unhooked

or damaged.

Verify that the ribbon frame

spring is not unhooked or

damaged.

If the spring is unhooked,

hook it back on. If it

damaged, replace it.

Table 4-2 Troubleshooting table for bad printing (continued)

Problem

Action

Checkpoint

Level

Probable cause

B

B

A

B

A

A

Summary of Contents for UP-250

Page 1: ...EXTERNAL PRINTER FEB 2000 MODEL UP 250 without price TECHNICAL MANUAL ...

Page 95: ... 86 END END Yes No Action 4 Replace main PCB Replace printer OK Action 4 mechanism assembly ...

Page 136: ... 127 ...

Page 149: ... 140 Main Circuit Board Parts Layout ...

Page 150: ... 141 RS 232 Serial Interface Circuit Board Parts Layout ...

Page 151: ... 142 IEEE 1284 Parallel Interface Circuit Board Parts Layout ...

Page 152: ...RS 485 Serial Interface Circuit Board Parts Layout 143 ...

Page 160: ... 151 Case Unit Lubrication Points Diagram 4 G 31 4 G 31 3 G 31 3 G 31 ...

Page 163: ... 154 EXPLODED DIAGRAM FOR TM U200B U210B NO 1 ...

Page 164: ... 155 EXPLODED DIAGRAM FOR TM U200B U200PB U210B U210PB NO 2 ...