10/97 M42.02.10.0 PAG.10

SAFETY RULES FOR MACHINE OPERATION

•

All operators of the surface planing-thicknessing machine should receive suitable training

about machine operation, adjustment and functioning, especially:

•

A) The machine functioning principles, correct operation and adjustment of fences,

callipers and guards, which must be used during processing.

•

B) The correct choice of tools and parameters.

•

C) The safe machining of the workpiece.

•

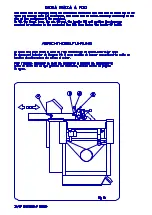

In order for the machine to operate efficiently and precisely, it must be installed correctly

and in a stable position (see pages 12-13-14-15). Enough space should be left around the

machine for the handling and stacking of the workpieces. Make sure that there is adequate

lighting and remove any obstacles which may create safety hazards.

•

Wear suitable work clothing. Do not wear garments with flapping parts such as scarves,

unbuttoned sleeves, etc.

•

Wear goggles or visors for eye protection.

•

Use knives which are sharp and in good condition. Tighten the screws, bolts or locking rings

of each tool to the required torque setting; do not exceed normal tightening values or use

levers and do not hit spanners.

•

Always use gloves when handling the knives.

•

Never operate the machine without the guards. Check regularly that these are in good

condition. If special machine processes are to be carried out, always use suitable guards.

•

Use piece-holding devices when machining short pieces.

•

Roller conveyors and table extensions should be used to support long pieces.

•

Even if the no-return hammers are operating perfectly, the working positions indicated on

page 25 “Correct work position” must be observed.

•

If the machine is stopped for cleaning or maintenance, turn the main switch to “0” and if

necessary fasten it with a padlock. Place a sign warning that the machine has been stopped

because of a breakdown or for repairs, maintenance, etc.

CAUTION

Summary of Contents for 530 DIGIR

Page 1: ......

Page 4: ......

Page 7: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 32: ......

Page 35: ......

Page 37: ......

Page 39: ...10 97 M42 02 03 0 PAG 3 ...