USER & PARTS MANUAL

CS940

25

5.B

SAWING

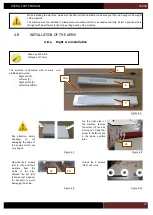

5.B.a

Setting the horizontal clamps

5.B.b

Setting the vertical clamps (optional)

Unlock the handle

(

3)

, then move the clamp assy

(5)

so its extremity (

B1)

is in a stable

position on the moulding. Release the pedal and check that the rubber (

B1)

will hold the

moulding firmly without causing it to tilt.

The back of the moulding must be against the cutting guide

(6)

and the moulding must

be flat on the table. It is important to make sure the moulding is locked in a stable

position during the cut. Repeat same sequence for the other vertical clamp.

3

5

B1

Press on the pedal to

release the clamps and to

be able to introduce the

moulding

inside

the

machine. Keep the pedal

pressed

during

the

adjustment

of

clamp’s

sequence.

6

Figure 5-8

Proceed in the same way for the other horizontal clamp.

The moulding must be installed with the rebate facing to the blades.

The 2 horizontal clamps (PH) must be set so the extremities (EB) are at about 1 cm from

the moulding.

Keep the pedal pressed.

Still with the pedal

pressed,

unlock

the

(M2) handle and adjust

the

position

of

the

horizontal clamps (PH)

to the contact of the

moulding,

then

backwards of 1 cm to

allow easy loading of

the moulding.

PH

M2

Figure 5-5

Figure 5-6

Figure 5-7

EB

Summary of Contents for CS 940

Page 1: ...USER PARTS MANUAL Version 5 05 2017 Z27456 Version 1 07 2014 ...

Page 12: ...USER PARTS MANUAL CS940 12 2 E CUTTING CAPACITY ...

Page 13: ...USER PARTS MANUAL CS940 13 2 F NEEDED SPACE ...

Page 37: ...USER PARTS MANUAL CS940 37 ...

Page 46: ...USER PARTS MANUAL CS940 46 2 E CAPACITE DE COUPE ...

Page 47: ...USER PARTS MANUAL CS940 47 2 F PLAN D ENCOMBREMENT ...

Page 71: ...USER PARTS MANUAL CS940 103 V CERTIFICATE CERTIFICAT DE CONFORMITE ...

Page 72: ...USER PARTS MANUAL CS940 104 ...