USER & PARTS MANUAL

CS940

28

5.B.f

Cut of the first piece

20

9

16

9

17

9

18

9

19

9

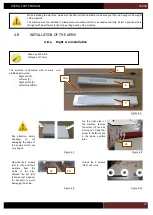

Make sure the blades are

rotating or press the button

(

18)

of the control panel to

switch on your blades.

Make sure the moulding is

against the measurement

stop.

Example

of

bad

positionning

of

the

moulding, the left clamp

will push the moulding

against the right blade

during the cut, causing

damage to the blade and

the moulding.

Figure 5-17

Figure 5-18

Release the pedal and

make sure the moulding is

hold firmly in place by the

clamps.

First, press the button (20)

and keep it pressed, then

pull down the right handle

to do the cut.

Figure 5-19

Adapt the mouvement to the type of material to be cut. Plastic must be cut in a fast motion whereas hard wood and

thick mouldings will require a slower movement. It is also advised to help the blades back movement, do not release

suddenly the handle which would result in a shock and vibrations which are not good for the quality of the cut and

the durability of the system. Keep the button (20) pressed during the complete cycle of the machine.

For your safety, releasing the button (20) while the right blade is not back up will stop the blade rotation.Press the

button (18) to restart the blades if needed.

If after a cut a piece of wood needs to be pushed out of the machine and is not accessible, do never introduce your

hands bellow the brushes. Push that piece using another piece of wood.

Summary of Contents for CS 940

Page 1: ...USER PARTS MANUAL Version 5 05 2017 Z27456 Version 1 07 2014 ...

Page 12: ...USER PARTS MANUAL CS940 12 2 E CUTTING CAPACITY ...

Page 13: ...USER PARTS MANUAL CS940 13 2 F NEEDED SPACE ...

Page 37: ...USER PARTS MANUAL CS940 37 ...

Page 46: ...USER PARTS MANUAL CS940 46 2 E CAPACITE DE COUPE ...

Page 47: ...USER PARTS MANUAL CS940 47 2 F PLAN D ENCOMBREMENT ...

Page 71: ...USER PARTS MANUAL CS940 103 V CERTIFICATE CERTIFICAT DE CONFORMITE ...

Page 72: ...USER PARTS MANUAL CS940 104 ...