22

319

2009301

Worm Gear cover

1

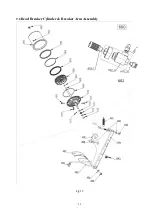

2012501 Parts of Motor Assembly (Fig.36)

400

2012501

Motor

1

406

6000192

Screw M8x35

4

401

4003101

Motor 220V 1.1KW

50HZ

(

standard

)

1

407

6000139

Washer 8x22x2

8

4002801

Motor380V 0.75KW

50HZ

(

optional

408

6000134

Washer 10x20x2

3

4003201

Motor 110V 1.1KW

60HZ

(

optional

)

409

6000336

Nut M10

4

402

2012701

Motor Pulley

1

410

3003601

Washer

6

403

6000130

Screw M6*10

2

411

6000199

WasherФ8

4

404

6000237

Belt A660

1

412

6000127

Nut M8

4

405

2012601

Motor Support

1

413

4004444

Capacitor

1

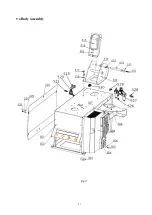

2065595 Parts of Body Assembly (Fig. 37)

501

2065596

Frame

1

516

6000348

Screw M6*10

1

502

2038701

Sign plate

1

517

6000187

Screw M10*55

6

503

3000101

Frame foot rubber

4

518

6000134

Washer 10*22*2

6

504

3005273

Robber buffer

1

519

Regulator base

1

505

6000253

Screw M6*16

5

520

4000701

Regulator

1

506

6000325

Washer 6*18*1.6

6

521

3005080

Union IPC 4-02

2

507

3005277

Rubber buffer

1

522

2065615

Side cover

1

508

2045001

Hanger

1

523

6000325

Washer 6*16*2

4

509

2065612

Column base

1

524

6000198

Washer φ6

4

510

6000184

Screw M10*25

4

525

6000431

Screw M6*16

4

511

2037401

Washer φ38*10*4

4

526

3005006

Union IPC 8-02

1

512

2065540

Pin

2

527

4004387

Oil mist

1

513

6000182

Screw M10*20

2

528

3005026

Union

1

514

6000123

Nut M10

2

529

3005010

Union IPL 8-02

1

515

3005272

Cover

1

530

4000901

Union

1

2064896 Pedal Assembly (Fig. 38)

531

2065616

Plate

1

556

2039301

Switch plate base

1

532

6000139

Washer 8*22*2

3

557

6000277

Screw M5*20

2

533

6000295

Screw M8*20

3

558

3005280

Switch handle

1

534

6000148

Nut M8

2

559

6000268

Screw M4*16

1

535

2065617

handle

1

560

2065754

Connecting rod

1

536

6000325

Washer 6*12*2

2

561

6000244

Screw M8*20

1

537

6000348

Screw M6*10

2

562

6000349

Screw M3*8

2

540

2065752

Pedal 1

1

563

6000134

Washer Ф10*22*2

1

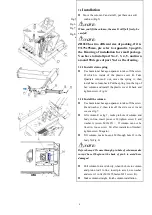

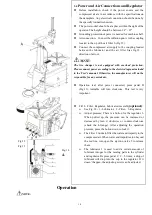

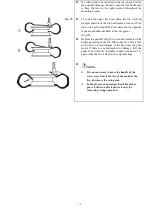

Summary of Contents for CASC506

Page 14: ...13 Fig 21 Fig 22 Fig 23...

Page 25: ...24 9 Exploded drawings 9 1 Column assembly Fig 34...

Page 26: ...25 9 2 Turntable assembly Fig 35...

Page 27: ...26 9 3 Gearbox motor assembly Fig 36...

Page 28: ...27 9 4 Body assembly Fig 37...

Page 29: ...28 9 5 Pedal Assembly Fig 38...

Page 30: ...29 9 6 Bead Breaker Cylinder Breaker Arm Assembly Fig 39...

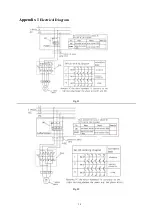

Page 31: ...30 Appendix 1 Electrical Diagram Fig 41 Fig 42...

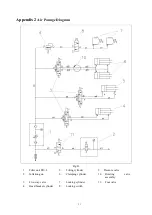

Page 33: ...32 Appendix 3 Drawing of installation for small package Fig 44...

Page 38: ...37 10 8 Exploded drawings...

Page 50: ......