23

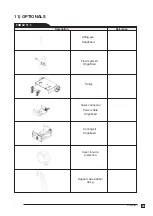

5) INSTALLING

5.1) Receiving the equipment

At receiving the ArcWeld 484 P.

Remove all the packaging material around the unit and check for

possible damages that could have happened during transport. Any complaints related to transport damage

should be directed to the Transport Company.

Remove carefully any material that could obstruct the refrigeration air system.

5.2) Working area

Several facts should be taken into consideration when determining the working place of a welding machine,

in order to have a safe and efficient operation. Adequate ventilation is needed for the refrigeration of the

equipment and for the operator’s safety. It’s extremely important that the area is kept clean.

The installation of any filter device in the environment restricts the air volume available for the machine

refrigeration which can cause overheating to the internal equipment. All guarantee undertakings from the

supplier cease to apply if the customer/user installs any filter device not authorized by the supplier.

N.B.:

In case the feeder is not installed immediately, keep it in its original

packaging or store it in a dry and well ventilated place.

14

13

ArcWeld 484 P

Summary of Contents for ArcWeld 484 P

Page 1: ...T CNICO Manual ArcWeld 484 P...

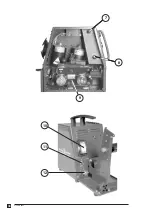

Page 6: ...ArcWeld 484 P 6 1 2 3 4 5 6 7 8 9 ArcWeld 484 P...

Page 7: ...7 10 11 12 14 13 ArcWeld 484 P...

Page 14: ...14 p gina intencionalmente em branco ArcWeld 484 P...

Page 15: ...16...

Page 21: ...22 10 11 12 7 8 9 ArcWeld 484 P...

Page 30: ...16...

Page 31: ...32 intentionally blank page ArcWeld 484 P...

Page 37: ...38 7 8 9 10 11 12 ArcWeld 484 P...

Page 46: ...16...

Page 47: ...48 p gina intencionalmente en blanco ArcWeld 484 P...