24

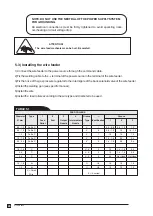

NOTE: DO NOT USE THE NEUTRAL OF THE POWER SUPPLY SYSTEM

FOR GROUNDING.

All electrical connections must be firmly tightened to avoid sparkling risks,

overheating or circuit voltage drop.

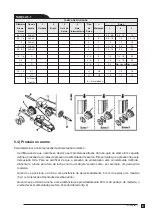

5.3) Installing the wire feeder

1)Connect the wire feeder to the power source through the command cable.

2)Fix the welding cable to the + terminal of the power source in the terminal of the wire feeder.

3)Fix the hose of the gas pressure regulator to the inlet nipple of the back solenoid valve of the wire feeder.

4)Install the welding gun (see specific manual).

5)Install the wire.

6)Install the feed rollers according to the wire type and diameter to be used.

Diameter

Ø mm

0,6 - 1,2

0,9 - 1,6

1,2

1,4 - 1,6

2,0 - 2,4

1,2 - 1,6

2,0

2,4

1,0 - 1,6

1,2

Type

Fe,Ss,C

Fe,Ss,C

Fe,Ss,C

Fe,Ss,C

Fe,Ss,C

C

C

C

Al

Al

C=Cored

Wire

1

Feed

Roller

2

Arm

3

Output

Nozzle

4

Intermediare

Nozzle

Groove

Type

V

V

V

V

V

V - K

V - K

V - K

U

U

=

Identification

1

6

7

2

2

3

3

4

U4

U4

1

0,6 - 0,8

0,9 - 1,0

1,2

1,4 - 1,6

1,4 - 1,6

1,2

1,2

2,4

1,0

1,2

2

0,9 - 1,0

1,2

1,2

2,0

2,0

1,4 - 1,6

1,4 - 1,6

Not Used

1,2

1,2

3

1,2

1,4 - 1,6

1,2

2,4

2,4

2,0

2,0

Not Used

1,6

1,2

K = Knurled

Groove

FEED ROLLERS

TABLE 5.1

ATTENTION!

The wire feed mechanism can be hurt. Be carefull.

ArcWeld 484 P

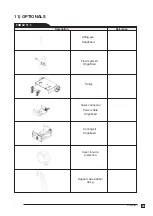

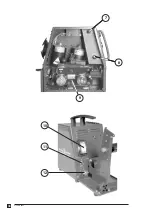

Summary of Contents for ArcWeld 484 P

Page 1: ...T CNICO Manual ArcWeld 484 P...

Page 6: ...ArcWeld 484 P 6 1 2 3 4 5 6 7 8 9 ArcWeld 484 P...

Page 7: ...7 10 11 12 14 13 ArcWeld 484 P...

Page 14: ...14 p gina intencionalmente em branco ArcWeld 484 P...

Page 15: ...16...

Page 21: ...22 10 11 12 7 8 9 ArcWeld 484 P...

Page 30: ...16...

Page 31: ...32 intentionally blank page ArcWeld 484 P...

Page 37: ...38 7 8 9 10 11 12 ArcWeld 484 P...

Page 46: ...16...

Page 47: ...48 p gina intencionalmente en blanco ArcWeld 484 P...