Section 4, Page 2

01/2001, CATTRON

- THEIMEG

TM

Maintenance Procedures.

Preventive Maintenance

is a periodic check of the system to keep it functioning at peak

performance. Preventive maintenance can also help prevent breakdowns and equipment outages

by identifying potential problems before they become real problems.

Corrective Maintenance

refers to fixing a problem once it has occurred. The goal of corrective

maintenance is to get the system back on line as quickly as possible with a minimum impact on

operations.

Preventive maintenance – PS Controllers.

Preventive maintenance for PS controllers is minimal because they are extremely durable and reliable

units. Preventive maintenance procedures are detailed in the following sub paragraphs:

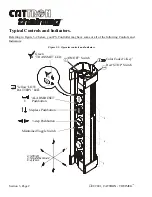

Daily Visual Inspection.

Before use, visually inspect the controller for cleanliness, physical damage, and security of

external parts (screws, switches, rubber grips, etc.). CATTRON-THEIMEG

™

emphasizes

that regular visual inspections not only mean quickly locating a source of potential problems,

but also may prevent serious problems from developing later.

Annual Netting Check.

Netting means that the receiver and transmitter of the radio control system are aligned on the

same frequency. It is very important that the receiver is exactly tuned to the frequency

required. This check should be done

once a year by a qualified radio technician utilizing

calibrated test equipment.

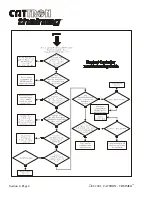

Troubleshooting – PS Controllers.

A basic Troubleshooting Guide is provided on page 4 of this section. When troubleshooting the

controller, the other major components of the remote control system (power supply and

receiver/decoder) should be fully operational. The operator should also be located within 500 feet (160+

meters) of the target receiver/decoder.

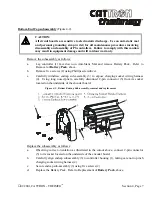

Corrective maintenance – PS Controllers.

Corrective maintenance for PS Controllers is restricted to replacing the Battery Pack, Rubber Side Grips,

Top End Cap sub-assembly, Bottom End Cap sub-assembly and Upper Main Body Housing. Refer to

the

Disassembly/Assembly

procedures below when removing and replacing items. On completion of

any assembly procedure and before placing the PS Controller into operational service, carry out a

Functional Check as follows:

Summary of Contents for i-Key

Page 2: ......

Page 14: ...Page xii 01 2001 CATTRON THEIMEG TM EZ CS AT Rx Rx Tx Tx Tx Rx Rx Rx ...

Page 20: ...Section 1 Page 6 01 2001 CATTRON THEIMEG TM This page intentionally left blank ...

Page 44: ...Section 4 Page 4 01 2001 CATTRON THEIMEG TM ...

Page 52: ...Section 4 Page 12 01 2001 CATTRON THEIMEG TM This page intentionally left blank ...

Page 68: ...Section 5 Page 16 01 2001 CATTRON THEIMEG TM This page intentionally left blank ...

Page 75: ... 01 2001 CATTRON THEIMEG TM Section 6 Page 7 Item 7 Carrying strap shoulder Part 42C 0057 ...

Page 89: ......