19

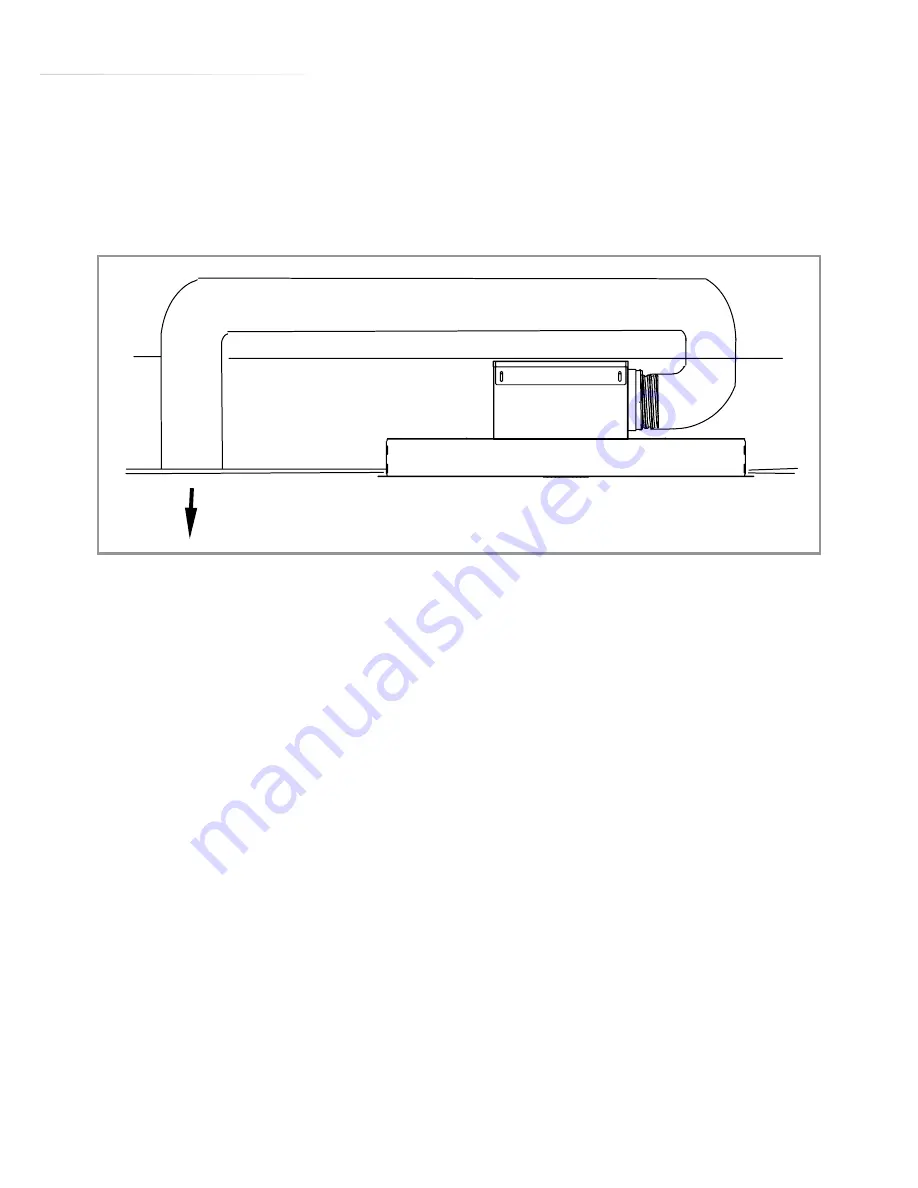

Re-Circulation:

An internal air vent is required, as shown below. This ensures that the

air is placed back in the kitchen after it has been filtered

Fit the charcoal filters to the body of the motor as shown in the

maintenance section of the manual.

Extraction:

The extractor is provided with a non-return butterfly valve which

should be fitted over the vent outlet before the ducting is fitted. This

prevents cold air being blown into the room from outside.

Securing the Duct to the Outlet:

Note that the duct pipe should be secured and sealed to the vent

outlet pipe / valve using appropriate ducting tape or a securing clamp.

fig. 18

Summary of Contents for EVX101

Page 21: ...21 Typical Installation Examples ...

Page 26: ...26 ...