7

6) Once welding has been completed remove any slag, switch

off the machine (which is only to be done when the fan is

not running), and close the gas cylinder.

Spot welding

The substantial difference with MIG-MAG welding is essential-

ly related to the torch and the adjustments that must be made

on the DH control panel.

• The gas guide nozzle specifically for spot welding must be

fitted on the torch (see Fig. C).

• On the DH control panel, select the spot welding mode and

set the time.

To begin spot welding:

• Press the torch button to start the welding current and wire

feed.

• When the spot welding time expires, the wire feed stops au-

tomatically.

• When the torch button is pushed again a new welding cy-

cle starts.

• Release the torch button.

FIG. C

Interval welding

The basic difference from spot welding is the addition of an ad-

ditional time known as the “stitch pause”.

On the DH control panel, select the interval welding mode and

then set the following times for it:

• Stitch time.

• Stitch pause.

To begin interval welding:

• Press the torch button to start the welding current and wire

feed.

• At this point the welding machine automatically carries out a

succession of welded portions followed by a pause, accord-

ing to the times entered previously. This procedure stops au-

tomatically only when the torch button is released.

• When the torch button is pushed again the torch begins a

new interval welding cycle.

Aluminium welding

To weld with aluminum wire proceed as follows:

• Replace the drive rolls with special ones for aluminium wire.

• Use a torch with a 3M cable and a carbon Teflon sheath.

• Set the pressure between the drive rollers at the minimum,

by turning the screw provided.

• Use argon gas at a pressure of 1,3 - 1,7 bar and regulate

the flow to a value between 14 and 20 lit/min to suit the cur-

rent used for welding.

Electrode welding (MMA)

On the

DIGITECH vision PULSE 3300-4000-5000

machine,

electrode welding is used to weld most metals (different types

of steel, etc.) using coated rutilic and basic electrodes with di-

ameters ranging from Ø 1.6 mm to Ø 6 mm, and devices that

the user can adjust for “Arc Force”, “Hot Start”, and Anti-stick-

ing functions to avoid the electrodes sticking.

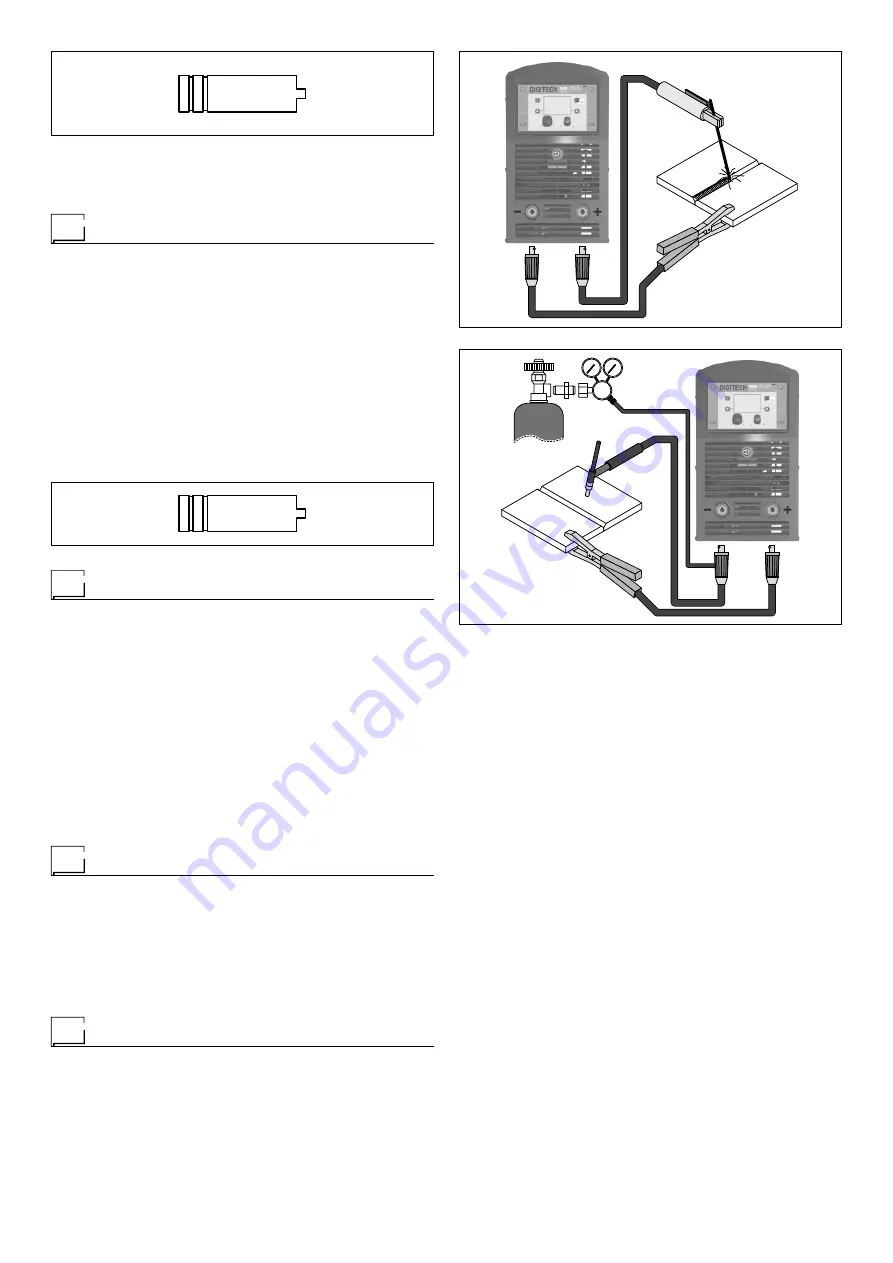

1) Connecting the welding cables (Fig. D):

Disconnect the machine from the mains power supply and

connect the welding cables to the output terminals (Posi-

tive and Negative) of the welding machine, attaching them

to the clamp and ground with the polarity specified for the

type of electrode being used (Fig.D). Always follow the

electrode manufacturer’s instructions. The welding cables

must be as short as possible, they must be near to one

another, positioned at or near floor level. Do not touch the

electrode clamp and the ground clamp simultaneously.

2) Switch the welding machine on by moving the power sup-

ply switch to

I

(Pos. 3, Fig. A).

3) Make the adjustments and do the parameter settings on

the control panel (for further information see the DH con-

trol panel manual).

4) Carry out welding by moving the torch to the workpiece.

Strike the arc (press the electrode quickly against the met-

al and then lift it) to melt the electrode, the coating of which

forms a protective residue. Then continue welding at an in-

clination of about 60° compared with the metal in relation

to the direction of welding.

PART TO BE WELDED

The part to be welded must always be connected to ground

in order to reduce electromagnetic emission. Much attention

must be afforded so that the ground connection of the part to

be welded does not increase the risk of accident to the user or

the risk of damage to other electric equipment. When it is nec-

essary to connect the part to be welded to ground, you should

make a direct connection between the part and the ground

shaft. In those countries in which such a connection is not al-

lowed, connect the part to be welded to ground using suitable

capacitors, in compliance with the national regulations.

FIG. D

FIG. E

FIG. C