______________________________________________________________________________________

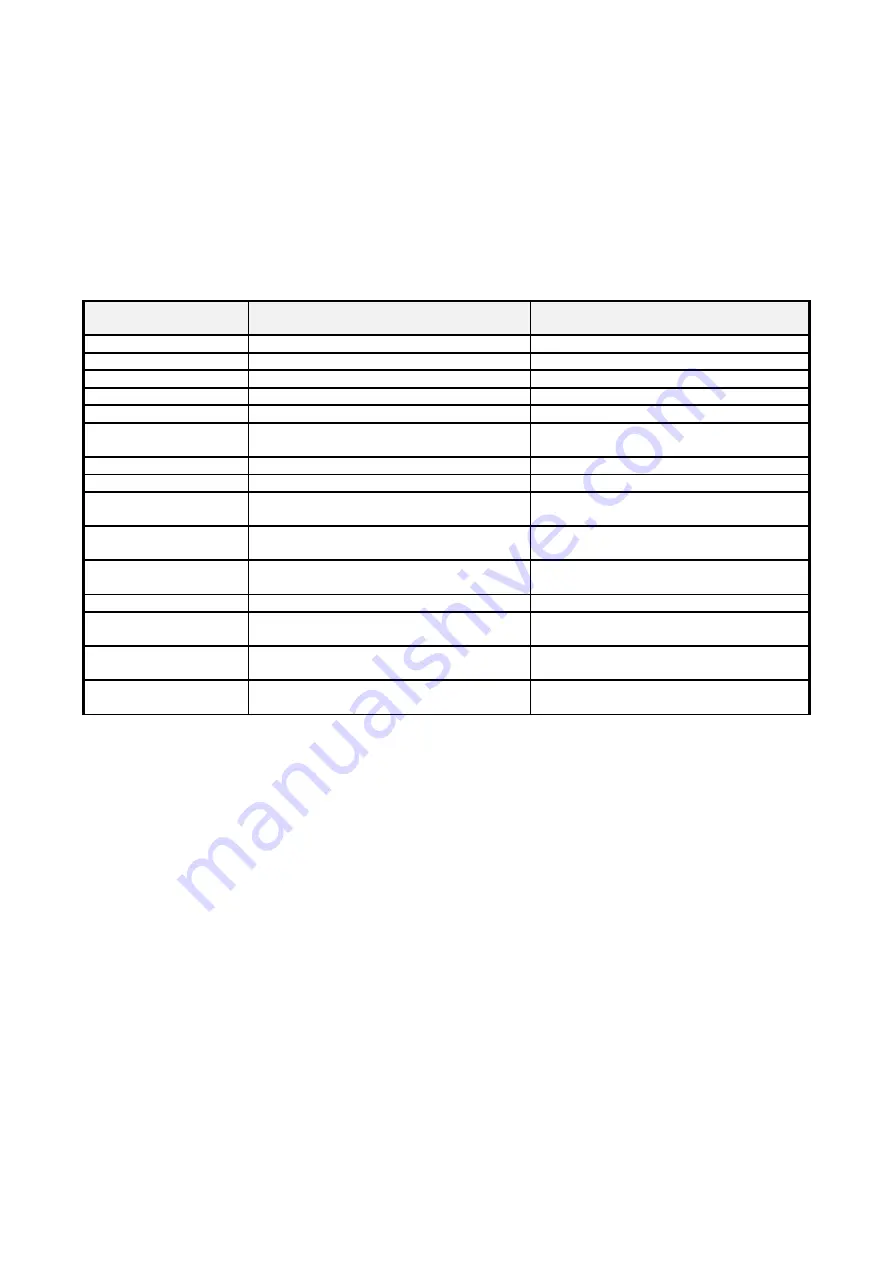

Sect. 8) Troubleshooting

When running a cycle the controller may signal one of the errors listed in the table below.

ERROR CODE

DISPLAYED

CAUSE

SOLUTION

ER21

Hardware fault

Contact the installer.

ER22

Reserved

Contact the installer.

ER23

Reserved.

Contact the installer.

ER24

Reserved.

Contact the installer..

ER25

Cycle in the memory with incorrect data. Program the cycle.

ER26

Attempted running of a cycle without any

steps being programmed.

Program the cycle.

ER28

Reserved.

Contact the installer.

ER31

Hardware fault.

Contact the installer.

ER41, ER42

Thermocouple continuity failure, not

connected or connected incorrectly.

Check the thermocouple and

connections.

ER43

Cold junction temperature sensor broken

or continuity failure.

Contact the installer.

EREC

Interrupted cycle recovery not initiated

(kiln temperature outside of set limit).

Run the cycle again.

ERAL

Reserved.

Contact the installer.

EAFS

Cycle stopped due to maximum end

step wait time (if programmed).

Check the heating elements or reduce

the kiln charge.

ALL1

Temperature signal outside of maximum

set limit. (See alarm relay).

Check the heating elements.

ALL2

Activation of alarm configured by

installer

Contact the installer.

______________________________________________________________________________________

10