CEBORA S.p.A.

14

3.300.188-B

04-03-2016

GB

4.2

External signals.

4.2.1

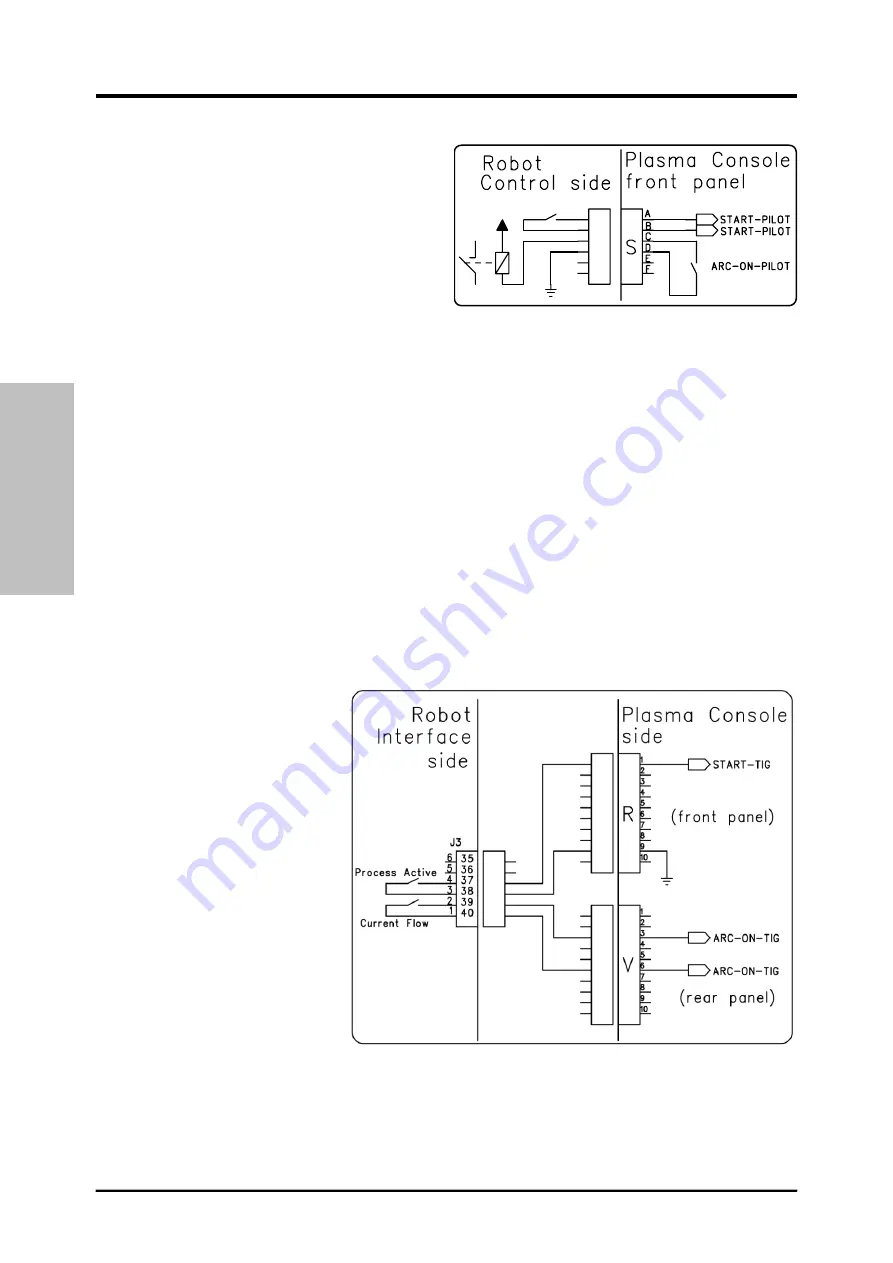

Connector S.

Terminals A - B, “Start-Pilot” signal.

Is the pilot arc strike command, delivered by the

Robot Control to the Power Source inside the

Plasma Console (30). Functionally is parallel

connected to the switch

I

on the Plasma Console

(30) front panel.

Contact closed = Start command.

Contact characteristic: 30 Vdc/125 Vac 0,5 Amax.

Terminals C - D, “Arc-on-Pilot” signal.

Is the pilot arc on signal, sent from Plasma Console (30) to Robot Control.

Contact closed = pilot arc lit.

Contact characteristic: 30 Vdc/125 Vac 0,5 Amax.

NOTE: The combination of these two signals, delivers also the indication on the Console Plasma state. To

forehead of the “Start-Pilot” signal the Console Plasma automatically puts into effect all the

processes for the pilot arc ignition (plasma gas output, generation of the pilot arc generator output

voltage, generation of the HF for the arc pilot strike, etc). If for any reason, as for example a

failure of the pilot arc generator inside the Console, the arc pilot is not ignited, the signal “Arc-

on-Pilot” is not activated. This condition, of “Start-Pilot” signal present, and “Arc-on-Pilot”

signal absent, can be considered anomalous. In such case contact the Cebora Service Department.

4.2.2

Connector R.

Terminals 1 - 9, “Start-Tig” signal (Process Active).

It is the retort of the welding Start command sent, via CAN bus, from the Robot Interface (25) to the

Power Source (21).

In the Plasma Console (30) it commands the solenoid valve opening and the spillage of the protection gas.

The protection gas flow begins with the “Start-Tig” signal but finishes automatically if within 3 seconds

does not arrive the “Arc-on-

Tig”signal; in such case in order to

restore the operation it is necessary

to inizialize newely the “Start-Tig”

signal (On - Off - On).

Contact closed = Start command.

Contact characteristic: 30 Vdc/125

Vac 0,5 Amax.

4.2.3

Connector V.

Terminals 3 - 6, “Arc-on-Tig”

signal (Current Flow).

Is the Tig arc on signal (welding in

act).

Is sent from Interface Robot (25) to

the Plasma Console (30), in order

to extend the flow of the protection

gas for all the welding lasting time.

The protection gas flow begins with

the “Start-Tig” signal, but it

finishes automatically if within 3 seconds does not arrive the “Arc-on-Tig” signal.

At the welding end, the lack of the “Arc-on-Tig” signal interrupts the protection gas flow.

Contact closed = Tig arc lit.

Contact characteristic: 30 Vdc/125 Vac 0,5 Amax.