73

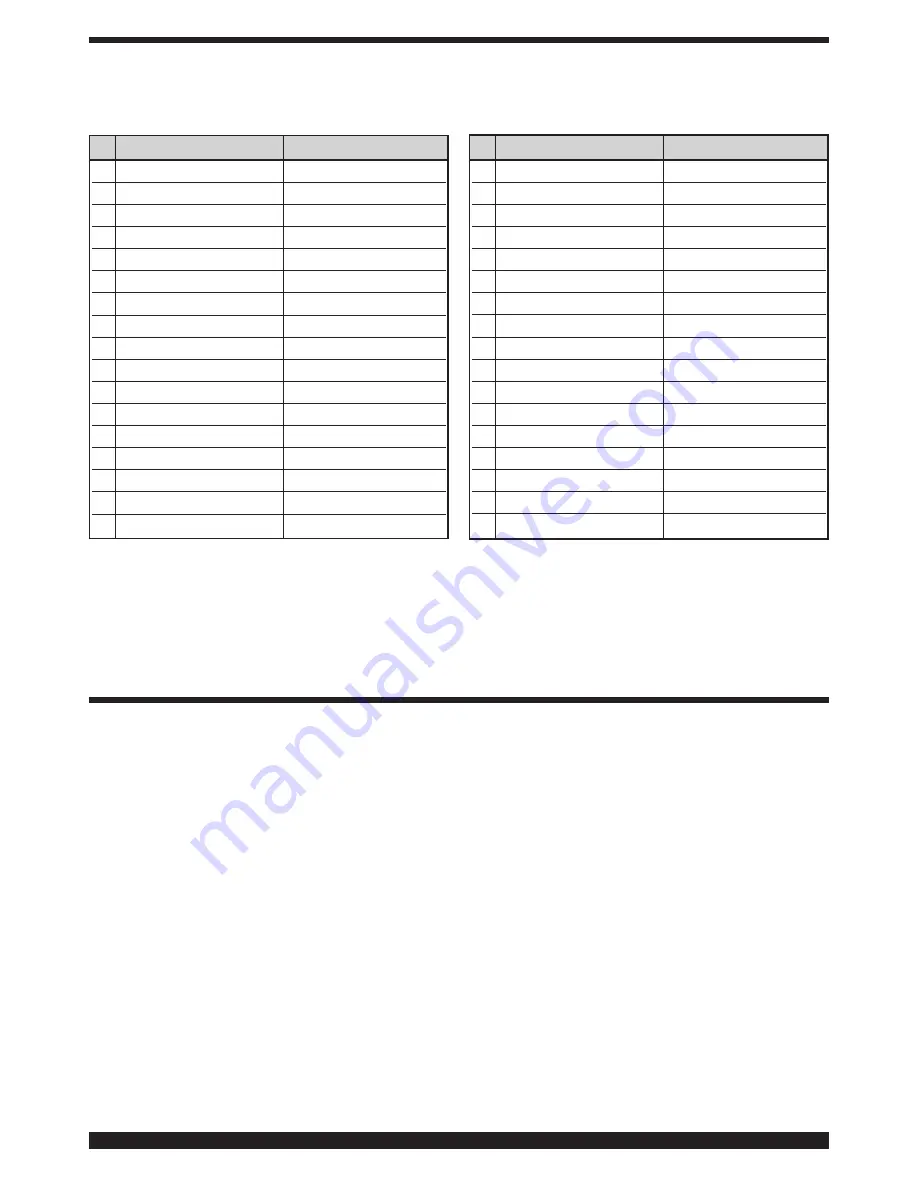

pos

DESCRIZIONE

DESCRIPTION

01

FASCIONE

HOUSING

02

SUPPORTO MANICO

HANDLE SUPPORT

03

MANICO

HANDLE

04

PANNELLO POSTERIORE

BACK PANEL

05

PRESSACAVO

STRAIN RELIEF

06

COPERTURA

COVER

07

INTERRUTTORE

SWITCH

08

CAVO RETE

POWER CORD

09

RACCORDO

FITTING

10

RACCORDO

FITTING

11

ELETTROVALVOLA

SOLENOID VALVE

12

RACCORDO

FITTING

13

PIEDE IN GOMMA

RUBBER FOOT

14

FONDO

BOTTOM

15

IMPEDENZA PFC

PFC CHOKE

16

TRASFORMATORE H.F.

H.F. TRANSFORMER

17

RACCORDO

FITTING

pos

DESCRIZIONE

DESCRIPTION

18

PRESA GIFAS

GIFAS SOCKET

19

RACCORDO

FITTING

20

SUPPORTO CIRCUITO

CIRCUIT BOARD SUPPORT

21

CIRCUITO FILTRO

FILTER CIRCUIT

22

PANNELLO ANTERIORE

FRONT PANEL

23

MANOPOLA

KNOB

24

SUPPORTO CIRCUITO

CIRCUIT BOARD SUPPORT

25

CIRCUITO DISPLAY

DISPLAY CIRCUIT

26

MOTORE CON VENTOLA

MOTOR WITH FAN

27

CIRCUITO CONNETTORE

CONNECTOR CIRCUIT

28

PIANO INTERMEDIO

INSIDE BAFFLE

29

COPERTURA

COVER

30

CIRCUITO DI POTENZA

POWER CIRCUIT

31

RACCORDO

FITTING

32

TAPPO

CAP

33

CORNICE

FRAME

When ordering spare parts please always state the machine item

and serial number and its purchase data, the spare part position

and the quantity.

La richiesta di pezzi di ricambio deve indicare sempre: numero di

articolo, matricola e data di acquisto della macchina, posizione e

quantità del ricambio.

Art. 265

Summary of Contents for BI-WELDER TIG 2040 DC-HF

Page 8: ...72 Art 265...

Page 10: ...74 Art 265...