4

Read these instructions before using the gauge.

Configuration may be easier before installation. Contact the

factory for assistance.

4

These products do not contain user-serviceable parts.

Contact us for repairs, service, or refurbishment.

4

Gauges must be operated within specified ambient tem-

perature ranges.

4

Outdoor or wash down applications require a NEMA 4X

gauge or installation in a NEMA 4X housing.

4

Use a pressure or vacuum range appropriate for the appli-

cation.

4

Use fittings appropriate for the pressure range of the gauge.

4

Due to the hardness of 316 stainless steel, it is recom-

mended that a thread sealant be used to ensure leak-free

operation.

4

For contaminated media use an appropriate screen or filter

to keep debris out of gauge port.

4

Remove system pressures before removing or installing

gauge.

4

Install or remove gauge using a wrench on the hex fitting

only. Do not attempt to turn gauge by forcing the housing.

4

Good design practice dictates that positive displacement

liquid pumps include protection devices to prevent sen-

sor damage from pressure spikes, acceleration head, and

vacuum extremes.

p

Avoid permanent sensor damage! Do not apply vacuum to

non-vacuum gauges or hydraulic vacuum to any gauges.

p

Avoid permanent sensor damage! NEVER insert objects into

gauge port or blow out with compressed air.

Gauges are not for oxygen service. Accidental rupture of

sensor diaphragm may cause silicone oil inside sensor to

react with oxygen.

Bipolar ranges read positive pressure and vacuum in the same

units, and zero with the gauge port open.

1000 psi and higher sensor are a sealed reference type. They

read zero with the gauge port open are internally referenced

to 14.7 psi. Functionally similar to gauge reference sensors.

Absolute reference gauges read zero at full vacuum and atmo-

spheric pressure with the gauge port open. With an open gauge

port the readings will vary continuously due to the effects of

barometric pressure.

Range Codes

The range code is part of the gauge model number and indi-

cates the default range when the gauge is ordered.

Selectable Ranges

Engineering units may be changed to any of those listed in the

same sensor range as shown in the range table.

Conversion

Engineering units are calculated from the factory default unit to

the newly selected units. The ranges listed under the psi sensor

range are rounded off.

Power-Up

Press and hold the front button for approximately 1 second.

The display is tested, the default full-scale range is indicated,

the full-scale range in the selected units are indicated, the

display is tested again, then the actual pressure and units are

displayed.

The backlighting will turn on for 1 minute and then auto-

matically shut off. Display backlighting can be turned on by

momentarily pressing the power button whenever the gauge is

on. This also restarts the auto shutoff timer.

The display backlighting will not be apparent under bright

lighting conditions.

Power-Up With Zero

This applies to gauge reference models only. Absolute refer-

ence gauges do not use the zero feature since they read

atmospheric pressure under normal conditions.

Be sure the gauge port is exposed to normal atmospheric pres-

sure and no pressure is applied. The zeroing function is only

activated at each power-up and the stored zero correction is

erased when the gauge is shut off.

Press and hold the front button. The display is tested and

then

oooo

is displayed. The gauge is now zeroed. Release

the button and the full-scale range in the selected units are

indicated, the display is tested again, then the actual pressure

and units are displayed.

Attempting to zero the gauge with pressure greater than

approximately 3% of full-scale pressure or vacuum applied

will result in an error condition, and the display will alternately

indicate Err 0 and the actual measured pressure. The gauge

must be powered down to reset the error condition.

Normal Operation

Following the start-up initialization, the display indicates the

pressure reading updated approximately 3 times per second.

The auto shutoff timer starts when the gauge is powered up or

whenever the button is pushed, unless the gauge shutoff time

was set to zero for on/off operation.

If excessive vacuum is applied to a pressure-only gauge, the

display will indicate -Err until the vacuum is released. Applying

vacuum to a gauge designed for pressure may damage the

pressure sensor.

If excessive pressure is applied (112.5% over range), an

out-of-range indication of 1 – – – or 1.–.–.– will be displayed

depending on model.

Minimum and Maximum Readings

Gauges are normally configured with minimum and maximum

capture functions enabled. One or both can be disabled in the

Advanced Configuration mode.

Minimum and maximum readings are continuously stored and

updated whenever the gauge is on. The stored readings can be

manually cleared if desired. The MAX and MIN memory is also

cleared whenever the gauge is off unless configured to save

the readings.

Press and hold the button for about 1 second until MAX is

displayed alternating with the units. The maximum reading will

be continuously updated. The gauge may be left in this mode.

After MAX is displayed, press and hold the button for about 1

second until MIN is displayed alternating with the units. The

minimum reading will be continuously updated. The gauge

may be left in this mode. If excessive vacuum is applied to a

pressure-only gauge while in this mode, the display will indi-

cate -Err until the MAX/MIN readings are cleared.

After MIN is displayed, press and hold the button again for

about 1 second until * * * * is displayed. The MAX and MIN

memory is not erased and the gauge returns to normal opera-

tion with the display indicating the current reading.

Press and continue to hold the button until the display indicates

clr MX/MN (about 3 seconds total) and then release the button.

Both maximum and minimum values are cleared and the gauge

returns to the normal mode and displays the current pressure.

Shut-Down

To shut off the gauge manually at any time, press and hold the

button until the display indicates OFF (about 5 seconds) and

then release.

When an auto shutoff timer is used, the display indicates OFF

five seconds prior to auto shutoff. The button can be pressed to

keep the gauge on. The auto shutoff and backlight (if equipped)

timers are reset whenever the button is pressed and released.

If the gauge is set up without auto shutoff (on/off operation)

it will stay on until manually shut off or until the batteries are

depleted. Turn gauge off when not in use to conserve battery

life.

Instructions

CTP1B

Operation—continued

Types of Gauges

Installation Precautions

Dimensions

Operation

Selectable Ranges

Function Button

Prompt (Release Button)

On

Press for 1

second

Display test > default units > selected

units

FUll scale

> display test >

actual reading

Zero

(gauge ref.

only)

Press and

hold

Display test >

oooo

> default units >

selected units

FUll scale

>

display test > actual reading

Hi reading Press/hold

Max

> max. reading & units

Lo reading Press/hold

MIN

> min. reading & units

Exit Hi/Lo Press/hold

SSSS

> actual reading

Clear Hi/Lo Press/hold

Max

>

Clr mx/mn

> actual reading

Clear, off

Press/hold

Max

>

Clr mx/mn

>

OFF

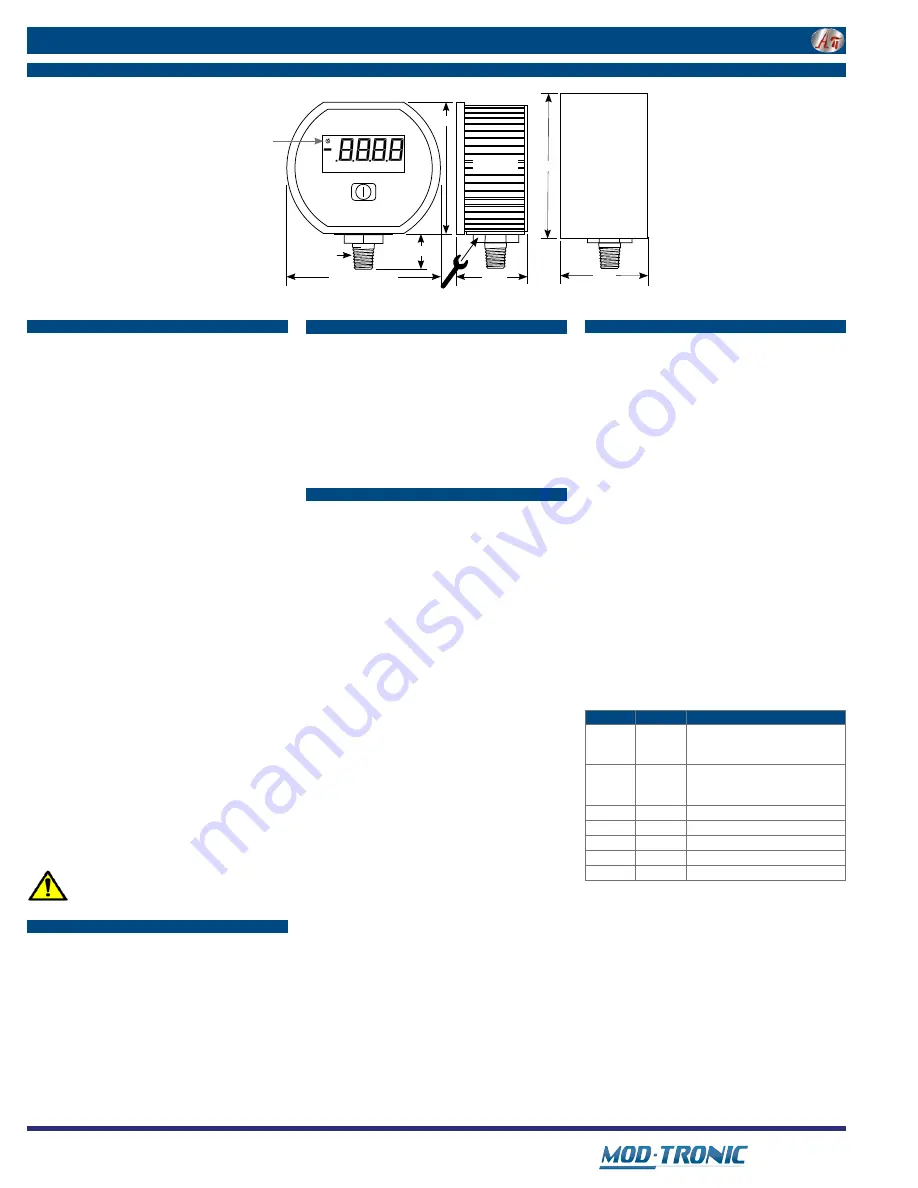

¼" NPT

2.88"

3.38" housing

3.67" with boot

0.75"

1.65"

Standard

X X X X X

88888

2

Low battery

voltage

indicator

Turn at hex fitting only

2.0"

3.19"

With boot

Cecomp maintains a constant effort to upgrade and improve its products.

Specifications are subject to change without notice. See cecomp.com for

latest product information. Consult factory for your specific requirements.

WARNING:

This product can expose you to chemicals including

lead, nickel and chromium, which are known to the State of

California to cause cancer or birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov

www.mod-tronic.com | sales@mod-tronic.com | 1-800-794-5883