25

SA5 OPERATIONS MANUAL & PARTS LIST

(Rev. 2/2020)

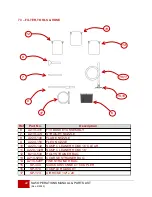

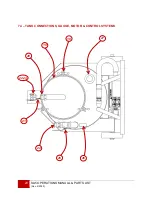

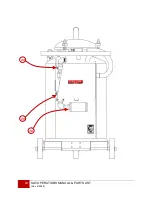

20

SP-405

QUICK DISCONNECT ADAPTER

21

SP-373

SECURITY CHAIN

22

SP-452

BLEED-OFF DISCONNECT CAP

23

SP-370

COUPLER GASKET

24

SP-368

QUICK DISCONNECT ADAPTER

25

SP-465

BUTTERFLY VALVE

26

SP-194

VACUUM / PRESSURE GAUGE

27

SP-382

RUPTURE DISC

28

SP-463

SELECTOR VALVE BUTTERFLY

29

SP-464

SELECTOR VALVE BUTTERFLY

30

SP-559

MUFFLER