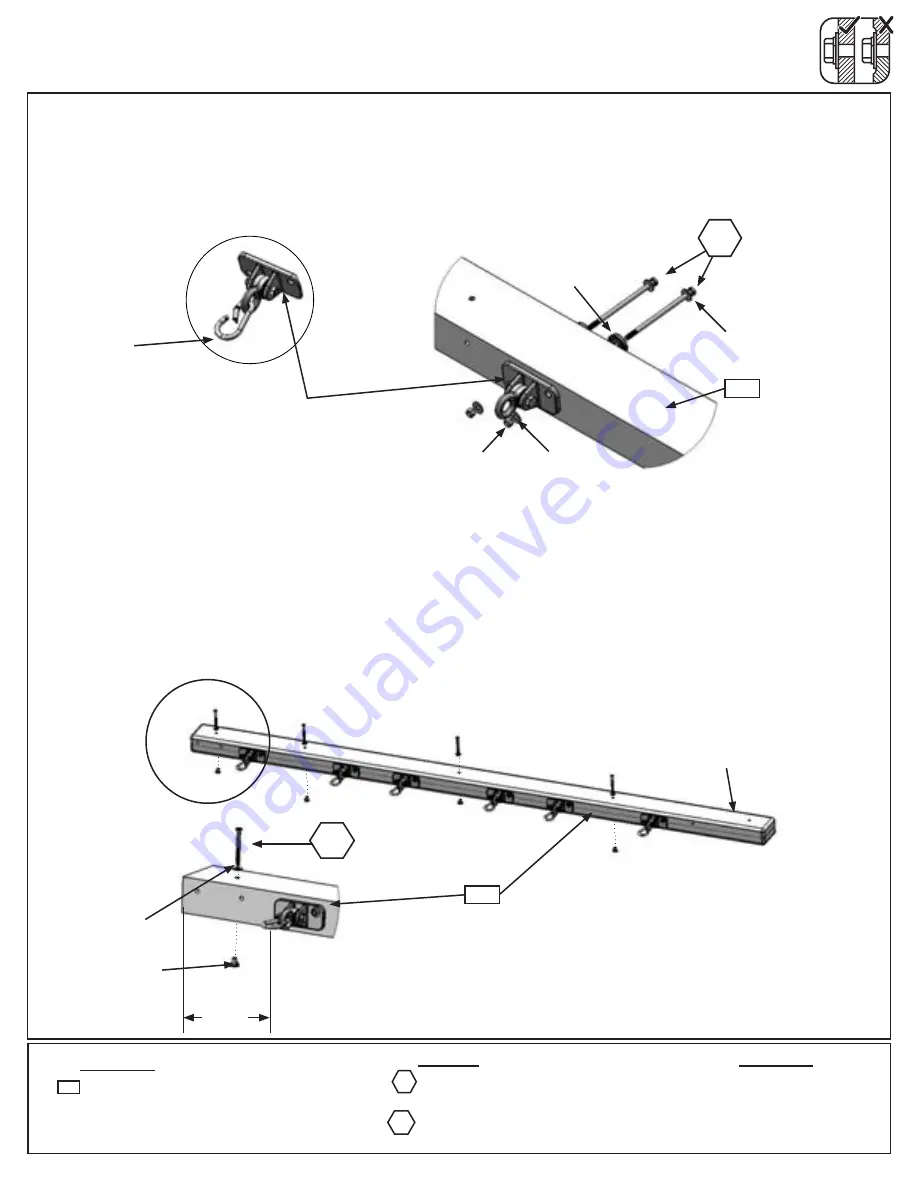

Step 26: Swing Beam Assembly

Hardware

A:

Attach 6 Heavy Duty Swing Hangers to (260) Engineered SW Beam using 2 (G13) 5/16 x 6-1/8” Hex Bolt

(with 2 flat washers, plastic formed washer and lock nut) per swing hanger, as shown in fig. 26.1.

B:

Attach 1 Quick Clip to each Heavy Duty Swing Hanger. (fig. 26.2)

12 x

5/16 x 6-1/8” Hex Bolt

(5/16” flat washer x 2, 5/16” lock nut

& plastic formed washer)

4 x

5/16 x 3” Wafer Bolt

(5/16” flat washer, 5/16” t-nut)

Other Parts

6 x Heavy Duty Swing Hangers

6 x Quick Clips

WB7

G13

Wood Parts

1 x

Engineered SW Beam FSC 3 x 5-1/4 x 110”

260

C:

Install 4 (WB7) 5/16 x 3” Wafer Bolts (with flat washer and t-nut) in (260) Engineered SW Beam, as shown in

fig. 26.3 and 26.4. A Wafer Bolt does not get installed on the Swing Side of the beam.

IMPORTANT! MAKE SURE ALL 4 BOLTS ARE ATTACHED. THEY WILL MINIMIZE CHECKING OF WOOD.

Fig. 26.2

260

5/16” Flat

Washer

Fig. 26.1

Fig. 26.3

Fig. 26.4

G13

Plastic

Formed

Washer

5/16” Flat

Washer

5/16”

Lock Nut

Heavy Duty Swing Hanger

260

5/16” Flat

Washer

5/16” T-Nut

WB7

Does not get

Wafer Bolt

Swing Side

Fort Side

9-3/4”

Quick Clip

95

support@cedarsummitplay.com