38

•

CEDIMA

® • Technical Documentation • All rights reserved according to ISO 16016 • Changes serving technical progress reserved •

Maintenance and care

CF•13.3 B / CF•13.3 B-L

ENGLISH

6.2

Performing regular visual checks

• Escaping process materials and lubricants,

• Escaping cooling or flushing water,

• Loose connections and connecting elements (saw blade

guard, handles, ...),

• Damage of operating elements (switches,...), indicators,

power sockets, plugs, connections, and/or the electric

system, electronics (if present), mechanical system, hous-

ing, …! ,

• Defective safety devices.

– Immediately take the joint cutter out of operation

if any of such damage as mentioned above occurs!

Repair the joint cutter!

DANGER

It is prohibited to keep working with the joint

cutter unless the damage mentioned above

have been repaired!

ATTENTION

Ensure operational safety of the joint cutter!

ATTENTION

Keep the safety and warning signs attached to the joint

cutter clean so that they remain readable even after

longer periods of time!

Replace any unreadable labels!

6.3

Relubrication, corrosion protection

• The joint cutter is largely protected against corrosion.

Regular checks and any repairs should be carried out to

preserve the corrosion protection!

– After cleaning and in case of longer periods on non-

use provide the metallic sliding parts and the movable

machine elements (e.g. lifting out spindle) with a thin

film of multipurpose grease and/or corrosion protec-

tion oil (forming oil)!

Excessive oiling and greasing promotes further wear due

to adhering dust and cutting slurry!

Multipurpose grease for the temperature range –20 to

120 °C (DIN 51 502, KP2K-20, NLGI-class, DIN 51 818)!

If possible, use biologically fast degradable lubricants and

formwork oils according to RAD-UZ64!

6.4 Engine

ATTENTION

Clean, service and care the joint cutter engine

according to the operating manual of the

engine!

In the operating manual of the engine you find important

information about adjustments, changing oil, air and fuel

filter and other maintenance work!

Clean the fan grids and the motor housing!

For instructions on how to service the joint cutter

engine refer to section 6.7.3!

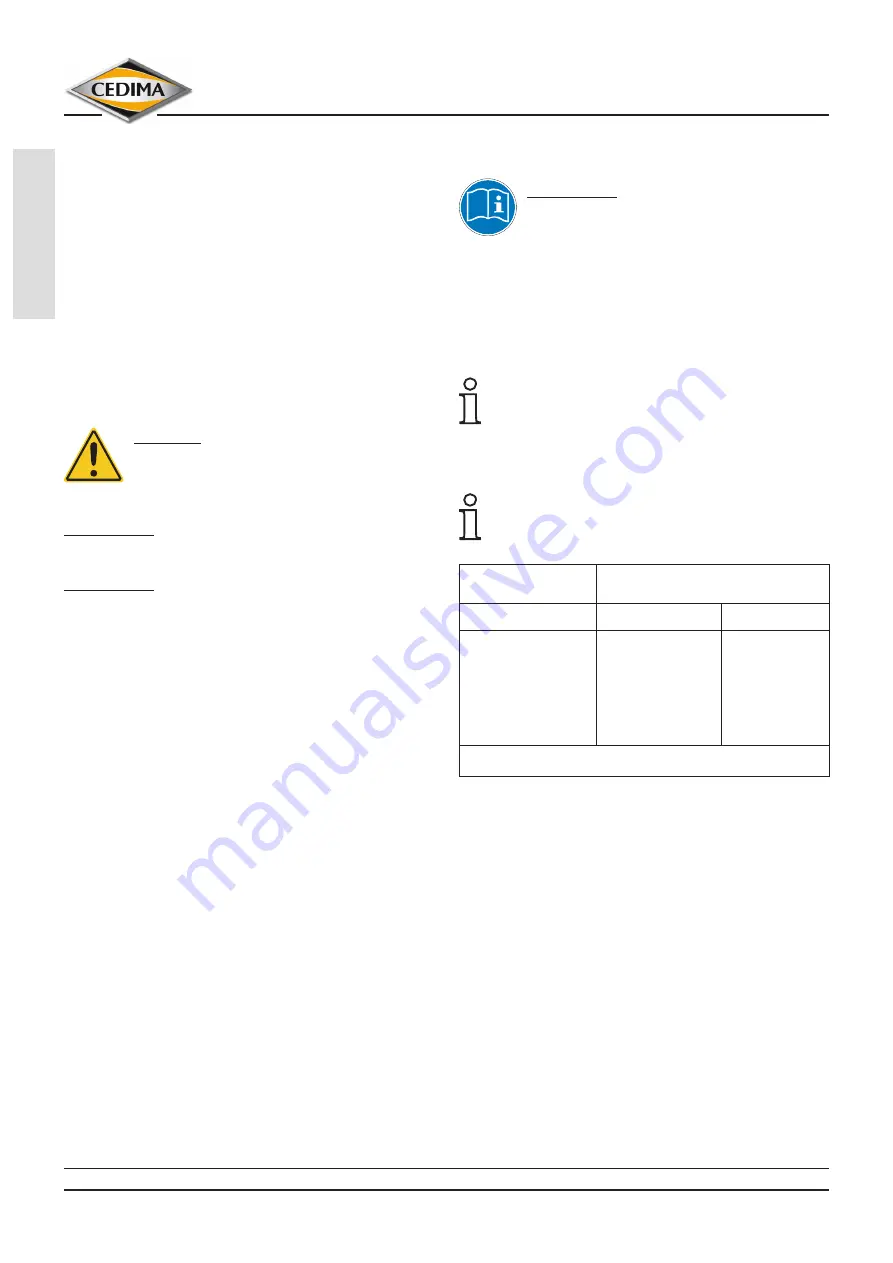

6.5

Tightening torques

The values refer to screws tightened with tools!

Coarse-pitch thread

tightening torque [Nm]

acc. to DIN ISO 262

matching the strength class

8.8

10.9

M 4

2.25

3.31

M 5

4.61

6.77

M 6

7.80

11.5

M 8

19.1

28.0

M 10

38.0

55.8

M 12

66.5

97.7

According to VDI directive 2230

Summary of Contents for CF 13.3 B

Page 55: ......