16/27

7. Maintenance

Switch the main switch to "0" and unplug before commencing maintenance work.

Removing the side panel and/or the lower protective caps easily accesses all adjustable

mechanical parts.

Do NOT start the machine before all safety guards are put back into place.

7.1 V-belts, chains and toothed belts

Tighten the v-belts and chains after approx. 14 days of use.

All grease nipples must be regularly greased with a grease gun.

The v-belts and toothed belts are supplied with tighten rollers and must be checked at least once a year

or after 1700 hours of operation.

7.2 Forward drive toothed belt (pos. 9011-20526)

Loosen the screws on the motor plate and tighten until the belt is taut.

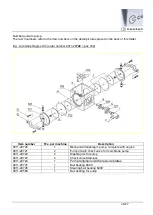

7.3 Chain to horizontal brushes (pos. 9016-20101)

Tighten by loosening the screw and changing position of sprocket wheel (pos. 9011-20559)

7.4 Resetting the brush arms

If the brush axle (pos. 9011-20510) has moved its setting or if the turn plate is leaking, it must be

tightened. The turn plate is bolted with 3 self-locking nuts. These must be tightened. If the turn plate is

still leaking after the executive of the above, replace the O-ring (pos. 9011-20591)

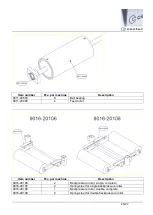

7.5 Pumps (Pos. 9011-20720)

There are two types of electric pumps, (Mono) or Ceetec membrane pumps. The oil in the gear motor of

each type of pump must be changed for the first time after 700 hours, and then after every 8000 hours.