Go to section

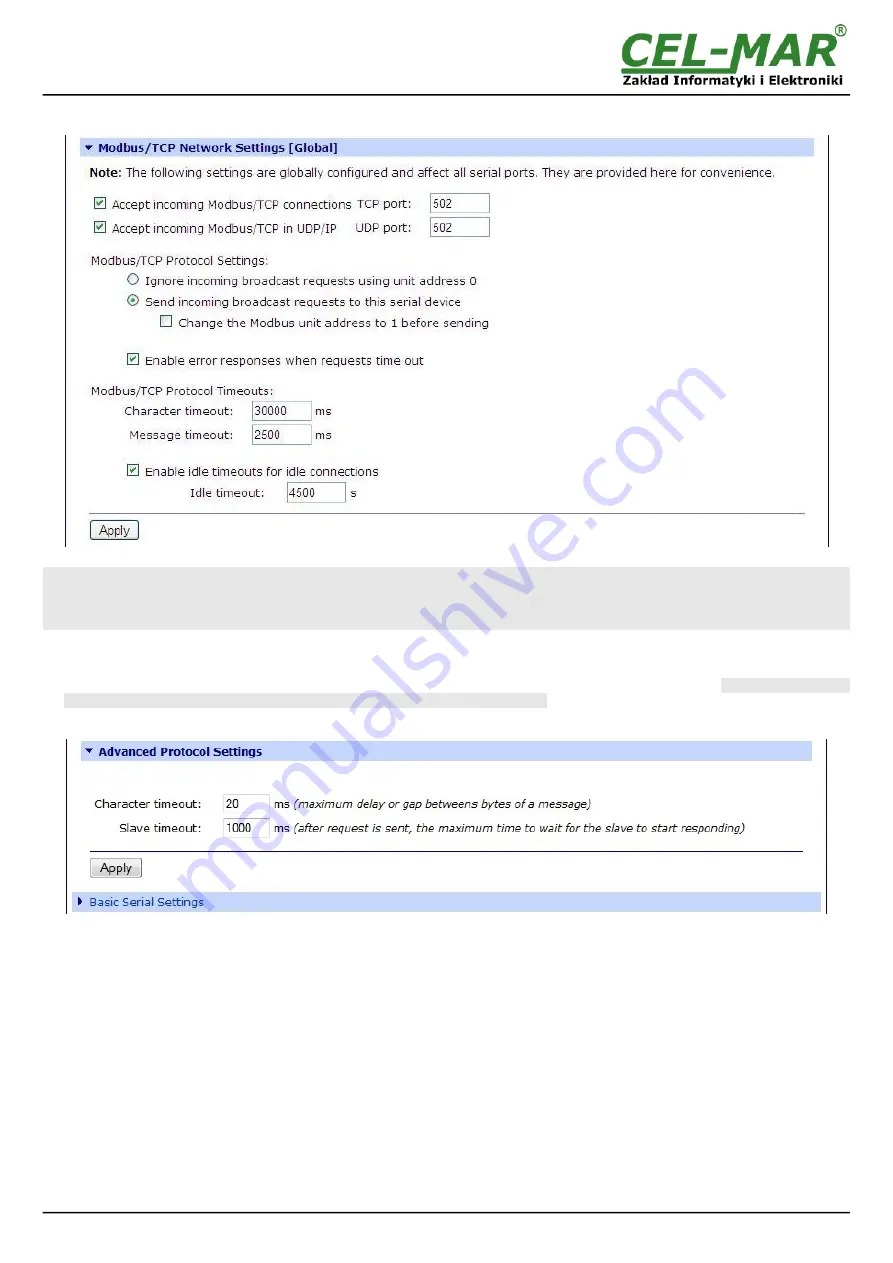

Modbus/TCP Network Settings [Global]

, configuration options set as on the figure below. Press

[Apply]

for saving

configuration.

Fig. 28. Example configuration for communication with MODBUS-SLAVE devices

ATTENTION !

Default port of Industrial Automation (Modbus Gateway) service is 502.

If on the local network is conflict with other network service using the same port, in the converter's port configuration

change number of port into another for the server and client service.

On section

Advanced Protocol Settings

(fig. below), set the time out by entry:

–

Character timeout

- value in ms., maximum delay or gap betweens bytes of a message – default 20 ms.

–

Message timeout

- value in ms., maximum delay or gap betweens bytes of a message – default 2500ms; this time not must be

less than the timeout set on MODBUS MASTER devices / SCADA/HMI software.

For saving the

Advanced Protocol Settings

press [

Apply

].

Fig. 33. Example configuration for communication with MODBUS-SLAVE devices – configuration of timeout parameters for

SLAVE type device

5.2.2.1.5.3. SERIAL PORT TRANSMISSION PARAMETERS

For proper operation of ADA-13021MG with devices Modbus-Master or Modbus-Slave types, connected to his serial port, should be

set the same transmission parameters for both devices.

Select

Basic Serial Settings

and enter

Baud Rate

,

Data Bits

,

Parity

,

Stop Bits,

the same parameter like has device connected to

the serial port of the converter.

5.2.3. SYSTEM SETTINGS

Select on left panel menu

Configuration -> System

and then on right will be selections as follows:

–

Device Identity Settings

– allows adding name of converter, describe the location and add identification number,

–

Simple Network Management Protocol Settings (SNMP)

– allows making the configuration of management protocol SNMP.

5.2.4. USERS CONFIGURATION

On the configuration page

Users

are two sections:

–

Users

26

ADA-13021MG