47

CHL-350 TECHNICAL MANUAL

03-2021

Translation of the original manual

It is very important to turn the general switch (a) to the OFF position and / or

disconnect the machine from the electric current before handling the elements inside

the electrical panel. It is very important to turn the general switch (a) to the OFF

position and / or disconnect the machine from the electric current before handling

the elements inside the electrical panel.

5. Unbalanced pressures:

Decompensation of pressures occurs when an obstruction in the hose or in the gun

prevents one of the components to be freely released through the gun chamber

when projected or when a problem in the pumping system prevents one of the

components from being able to reach the gun in the required amount.

To determine whether decompensation occurs as a result of an obstruction or as a

result of a problem in the pumping system, project with the gun, observe the

pressure indicated on the pressure on the pressure gage (

q,v

) in the other

component: if the pressure of the missing component is higher, decompensation is

the result of an obstruction. If the pressure is lower, decompensation is the result of

a problem in the pumping system.

6. Cavitation

Cavitation occurs when the pumping system requires a greater volume of material than

that supplied by the feeding system, leading to the formation of a vacuum in the dosing

pump. The causes that can cause cavitation are as follows:

a. The transfer pump fails to supply the required volume. The problem may be

that the pump does not meet the required characteristics, the lack of air

supply to the pump or that the pump is faulty. A 2:1 ratio pump is

recommended for isocyanate transfer and a supply hose with a minimum

internal diameter of 20mm.

b. High viscosity. Polyurethane foaming systems normally require a minimum

transfer temperature of 12ºC. With lower temperatures, the product

increases its viscosity making pumping difficult. When environmental

conditions do not allow the products to be kept at a minimum temperature of

12ºC, auxiliary heating elements must be used to adapt the products to the

minimum temperature required for transfer.

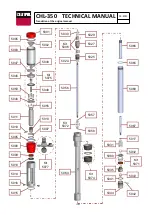

c. The product inlet filter is obstructed (ref.2100-A).

d. There has been wear and tear on the gaskets or pump seals preventing the

supply of the required product.

7. Failure in the ends of stroke in change of direction.

Summary of Contents for CHL-350

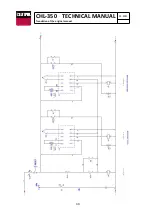

Page 33: ...33 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual 14 ELECTRICAL DIAGRAMS ...

Page 34: ...34 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

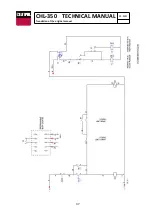

Page 35: ...35 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

Page 36: ...36 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

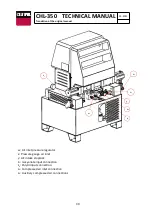

Page 37: ...37 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...

Page 60: ...60 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual 28 CE DECLARATION ...

Page 61: ...61 CHL 350 TECHNICAL MANUAL 03 2021 Translation of the original manual ...