7

Ver. 05-2015

ENGLISH

Use and maintenance manual

Starting

3.

Starting

WARNING

b

efoRe

sWITchING

oN

The

mAchINe

,

mAke

suRe

ThAT

All

The

coNNecTIoNs

descRIbed

IN

The

INsTAllATIoN

chApTeR

hAve

beeN

mAde

coRRecTly

.

T

he

folloWING

opeRATIoNs

INvolve

A

poTeNTIAl

RIsk

foR

The

opeRAToR

,

GIveN

The

pReseNce

of

volTAGe

oN

The

equIpmeNT

. T

he

p

eRsoNAl

p

RoTecTIve

e

quIpmeNT

descRIbed

IN

The

INsTAllATIoN

mANuAl

musT

be

WoRN

ANd

WoRk

musT

be

doNe

WITh

due

cARe

ANd

ATTeNTIoN

.

o

peRATIoNs

mAy

oNly

be

peRfoRmed

by

A

specIAlIsed

TechNIcIAN

.

Before powering the machine, carry out the following

checks:

1. Check that the balancing machine touches the floor

at the three support points.

2. Make sure that all the parts of the balancer are cor-

rectly connected and fixed.

3. Make sure that the parameters (voltage and frequency)

of the mains power supply are compatible with those

indicated on the rating plate of the balancer.

4. Make sure the power cable is correctly connected.

5. Make sure the machine shaft and flange hole are

clean.

cAuTIoN

A

Ny

TRAces

of

dIRT

mAy

AffecT

bAlANcING

AccuRAcy

.

6. To turn on the wheel balancer press the switch on

the left-hand side of the machine.

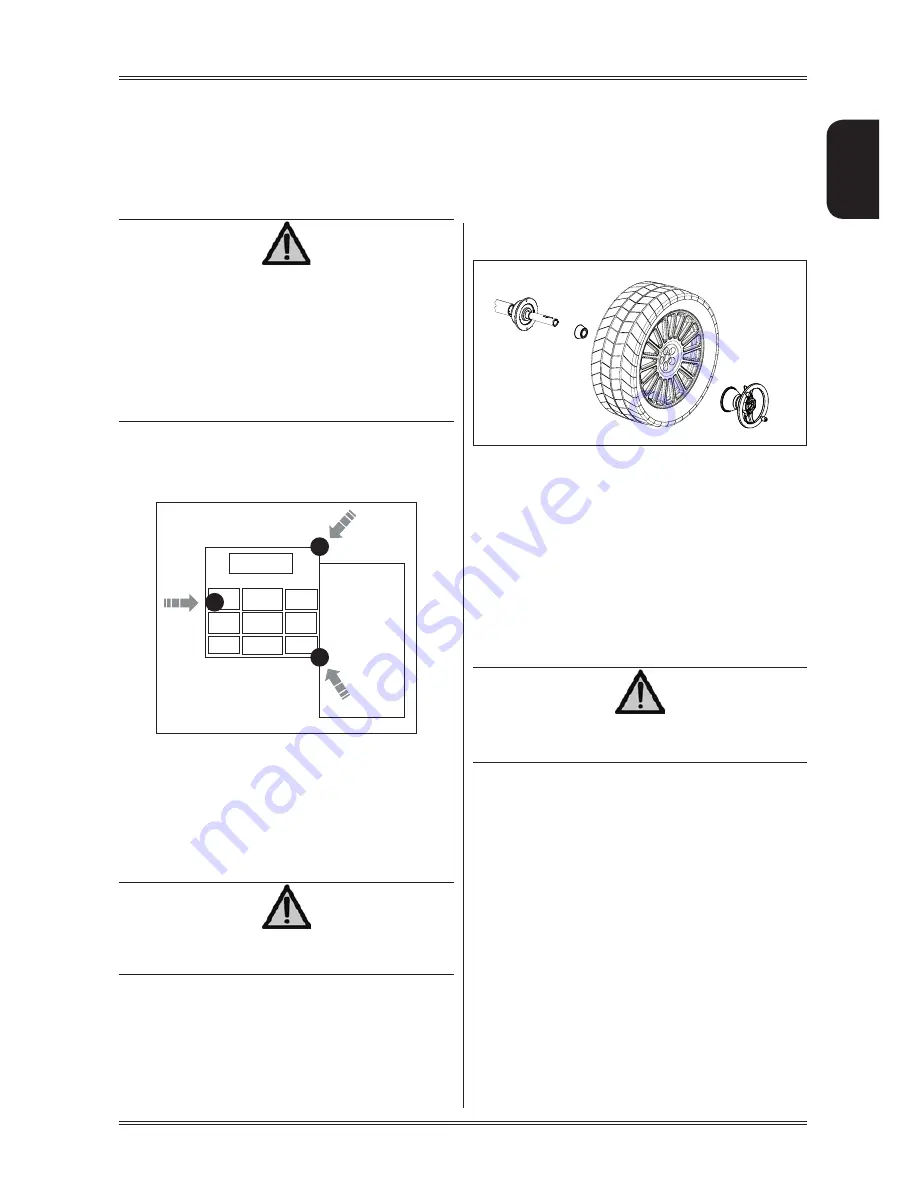

7. Position the wheel on the terminal with the inner part

facing the balancer.

8. Firmly attach the wheel to the balancer shaft using

the lock nut.

9. At this point, you can read the tyre measurements

and perform balancing.

10. To perform the spin, lower the splash guard, when

fitted and, if necessary and available, press the

START button.

11. The wheel is automatically locked when reaching

the correct angular position for weight application

on the inside and outside.

To unlock the wheel, turn it hard to move it from the

correct correction position. If the unbalance is

within tolerance, the wheel is locked automatically.

WARNING

I

T

Is

pRohIbITed

To

Touch

ANy

pART

of

The

mAchINe

duRING

The

bAlANcING

cycle

.