10

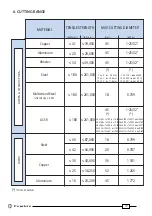

6. CUTTING RANGE

MAX CUTTING DIAMETER

Steel

≤ 30

≤ 16

≤ 25

≤ 60

MATERIAL

≤ 41

≤ 20

≤ 34

45

≤ 42

Multi-strand Steel

(strands qty. ≥ 200)

≤ 180

18

Steel

≤ 180

ACSR

≤ 180

45

(*)

26 x 2,50 + 7 x 1,95 : ø = 15,85

26 x 3,06 + 7 x 2,38 : ø = 19,38

26 x 3,60 + 7 x 2,80 : ø = 22,80

54 x 3,50 + 19 x 2,10 : ø = 31,50

54 x 4,36 + 19 x 2,62 : ø = 39,20

7 x 3,0 : ø = 9,0 mm

19 x 2,1 : ø = 10,5 mm

19 x 2,3 : ø = 11,5 mm

TENSILE STRENGTH

Copper

45

45

Aluminium

Almelec

Copper

Aluminium

(*)

TYPICAL EXAMPLES

(*)

(daN/m m

2

)

(lbs/sq.in.)

≤ 59,450

≤ 29,000

≤ 49,300

≤ 261,000

18

20

30

32

45

≤ 43,000

≤ 23,200

≤ 36,250

≤ 87,000

≤ 60,900

≤ 261,000

(mm)

(inches)

1-25/32”

1-25/32”

1-25/32”

7 x 0.118 = ø out.0.354

19 x 0.083 = ø out. 0.413

19 x 0.091 = ø out. 0.453

(*)

≤ 261,000

0.709

26 x 0.098 + 7x 0.077 : ø out 0.624

26 x 0.120 + 7x 0.094 : ø out 0.763

26 x 0.142 + 7x 0.110 : ø out 0.897

54 x 0.138 + 19x 0.082 : ø out 1.240

54 x 0.172 + 19x 0.103 : ø out 1.543

1-25/32”

(*)

0.709

0.787

1.181

1.260

1.772

ROPES & CONDUCTORS

RODS

Summary of Contents for B-TC450A

Page 11: ...11...