9

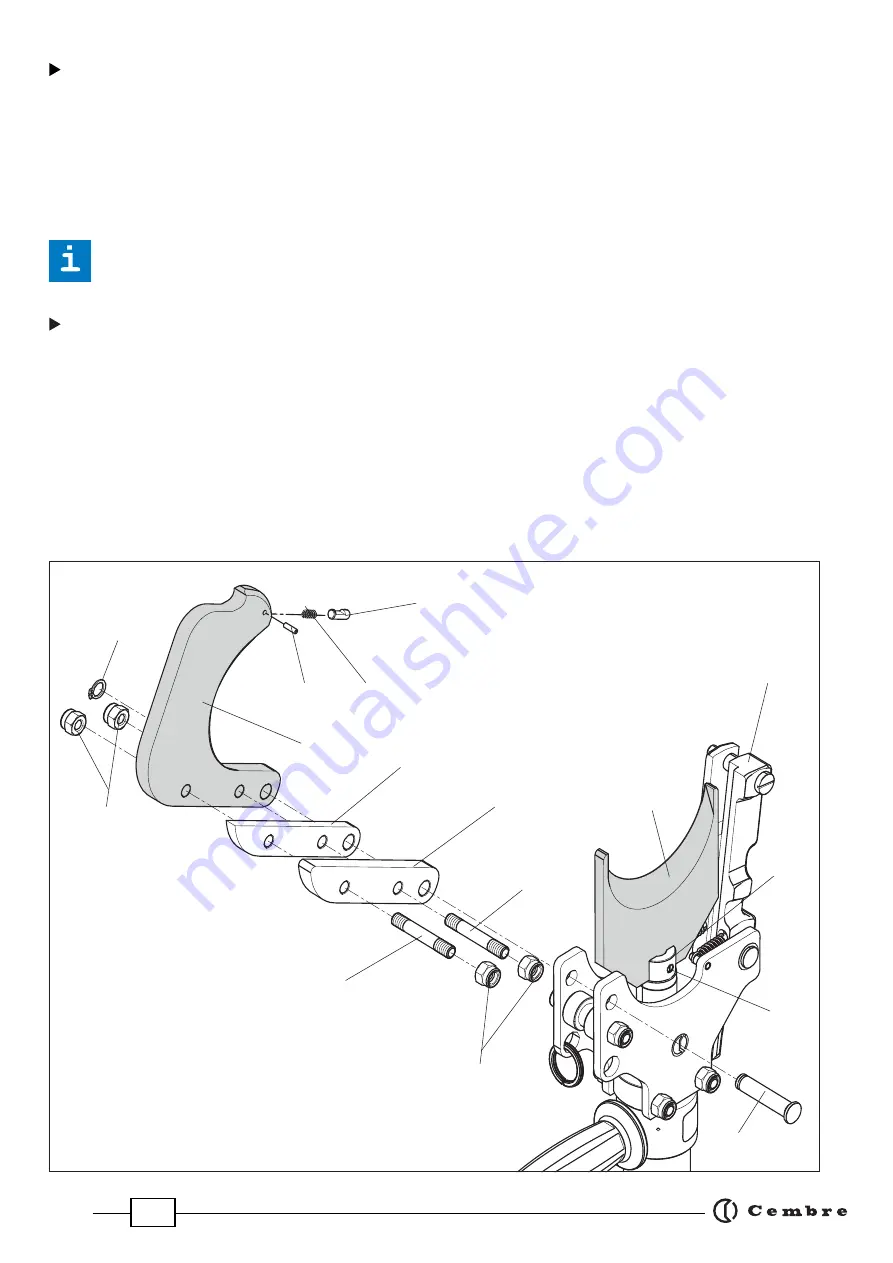

FIG. 6

99

3

100

101

2

98

99

37

13

1

97

103

102

38

98

18

Lower blade

– Press lever (1) and open upper blade assembly.

– Operate tool to advance the lower blade (3) until holding screw (18) is visible on the ram (13),

than remove the battery from the tool.

– Using a fl at blade screwdriver remove the holding screw (18) and release the lower blade (3).

– Insert the new blade and fi t the holding screw.

Before closing the tool head, release the oil pressure and retract the lower blade, otherwise

the tool head assembly may hit and damage the lower blade.

Upper blade

– Press lever (1) and open upper blade assembly.

– Remove circlip (38) and pin (37).

– With a 13 mm spanner, undo M8 nuts (98) and remove two studs (99), blade guide (100) blade

spacer (101) and upper blade (2), noting the order of assembly.

– With a punch, drive out the split pin (102), collecting the spring (103) and the pin (97).

– Assemble the spring (103) and the pin (97) on the new blade, locking the whole by the split pin

(102).

– Fitting the new blade is a reversal of the above.

Summary of Contents for B-TC950A

Page 11: ...11...