9

ENGLISH

5.1) Topping up the hydraulic oil

(Ref. to Figs. 7 and 8, page 36)

Periodically check, at least every 6 months, the oil level in the pump.

– Position the pump on its base on a fl at surface.

– Completely discharge the oil pressure by pushing the pressure release button (PS).

– Remove cap (TL) and check the level of the oil, if necessary

slowly add oil

.

NEVER REFILL OVER THE MAXIMUM LEVEL to leakage during operation.

–

When refi lling is fi nished replace the cap (TL).

Should it be necessary to remove oil from the reservoir, drain by removing the cap with magnetic

insert (TV) (Fig. 7) located on the bottom of the pump.

Clean cap (TV) of any metallic deposits before replacing it.

Always use clean recommended oil, see § 1.

Do not use old or recycled oil.

Do not use hydraulic brake fl uid.

Ensure that used oil is disposed of in accordance with current legislation.

5.2) Protection fuses

The pump is equipped with two protection fuses:

F1

: fuse 10A (5X20) for protection of

electric motor

F2

: fuse 2A (5X20) for protection of

24V control circuits.

In case of replacement, use only

equivalent fuses.

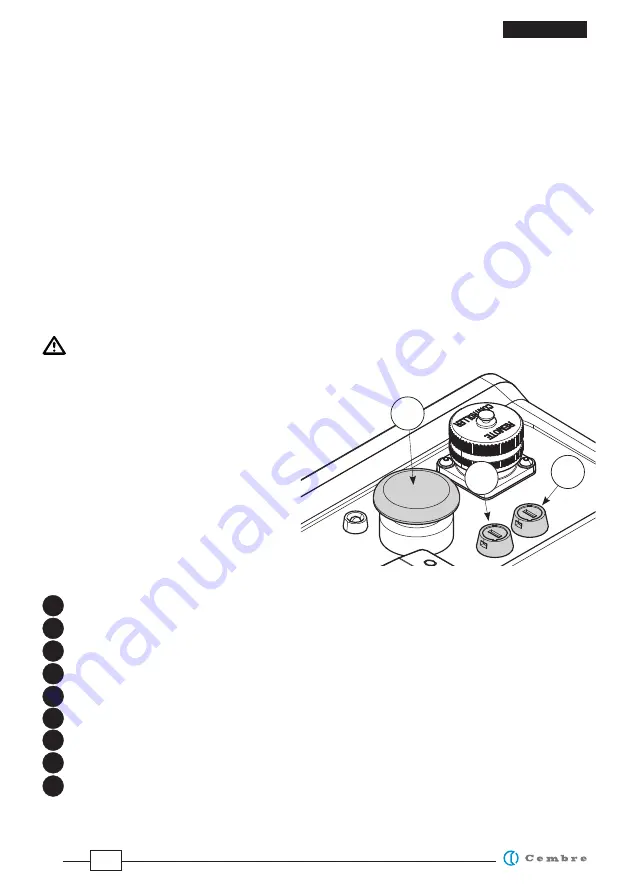

5.3) Internal electrical panel components

(Ref. to Fig. 8, page 37)

450V

16μF

MOTOR RUNNING CAPACITOR

450V

40μF

MOTOR

STARTING

CAPACITOR

24

V

DC

OIL

RELEASE

VALVE

24

V

DC PRESSURE SWITCH

CURRENT RELAY

6,8 K

CONDENSER

DISCHARGE

RESISTOR

ELECTRONIC

CARD

OPERATING

RELAY

TRANSFORMER

F2

F1

PS

C

C1

EV

PR

RC

R

SE

TL

TR