4

ENGLISH

4. INSTRUCTION FOR USE

4.1) Setting

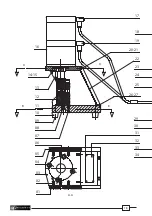

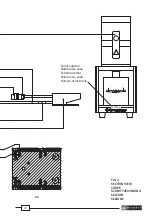

(Ref. to Fig. 2)

The press is free standing and supplied

ready to use by connecting the pneumatic

coupler (25) on the manual control (30) to

an air supply at 6 bar pressure.

4.2) Operation

For a complete cycle, (compression and

release) briefly press the control: do

not keep the control depressed other-

wise the press may continue to cycle.

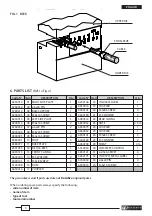

To perform a crimping operation:

– Fit the cable into the end sleeve.

– Insert the cable and the end sleeve

through the appropriate aperture in

the guard until positively located on

the the lower die (Ref. to Fig. 1).

– Operate the press using the control (30).

– Release the control.

– Remove the crimped joint.

5. MAINTENANCE

(Ref. to Fig. 2)

All maintenance operations must be carried out with the press disconnected from the air supply

by detaching the connection (25).

The press is robust and does not require special attention; to maintain the correct operation, pro-

ceed as follows:

5.1) Accurate cleaning

After use clean the press with a clean cloth, to remove dust and dirt particles.

Periodically, open the rear casing (22) by removing the fixing screws (20 and 26).

Use a pneumatic blowgun to remove residuals from the mechanism, dies and guards.

Periodically the compression area must be cleaned as follows:

– Remove the two screws (15) and remove the front protection (13).

– Remove the screw (08) which holds the die block and slide it out from the front.

– Slide out the top die making sure not to lose the spring and, using a clean cloth remove any dirt

which may be present.

– Replace the spring, place the top die and the protection in their original positions and tighten

the relative locking screws (08 and 15).

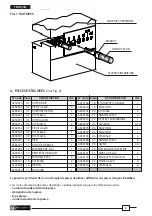

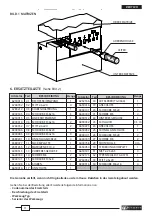

0.3

PKC306

PKE308

PKC308

0.5

PKD506

KE506ST

PKD508

PKE508

PKC508

KE508ST

PKD510

PKC510

0.75

PKD7506

KE7506ST

PKD7508

PKE7508

PKC7508

PKD7510

KE7508ST

PKD7512

PKC7512

1.0

PKD106

PKT508

KE106ST

PKD108

PKE108

PKC108

PKT510

PKD110

KE110ST

PKD112

PKC112

1.5

PKD1508

PKE1508

PKC1508

PKT7508

KE1508ST

PKD1510

PKE1510

PKC1510

PKT7510

KE1510ST

PKD1512

PKD1518

PKE1518

PKC1518

2.5

PKD2508

PKE2508

PKC2508

PKT108

KE2508ST

PKT110

KE2510ST

PKD2512

PKE2512

PKC2512

PKT1508

PKD2518

PKE2518

PKC2518

PKT1512

4

PKD410

PKE410

PKC410

PKT2510

KE410ST

PKD412

PKE412

PKC412

PKT2512

KE412ST

PKD418

PKE418

PKC418

6

PKT412

KE610ST

PKD612

PKE612

PKC612

KE612ST

PKD618

PKE618

PKC618

KE616ST

10

PKD1012

PKE1012

PKC1012

PKT614

PKD1018

PKE1018

PKC1018

KE1016ST

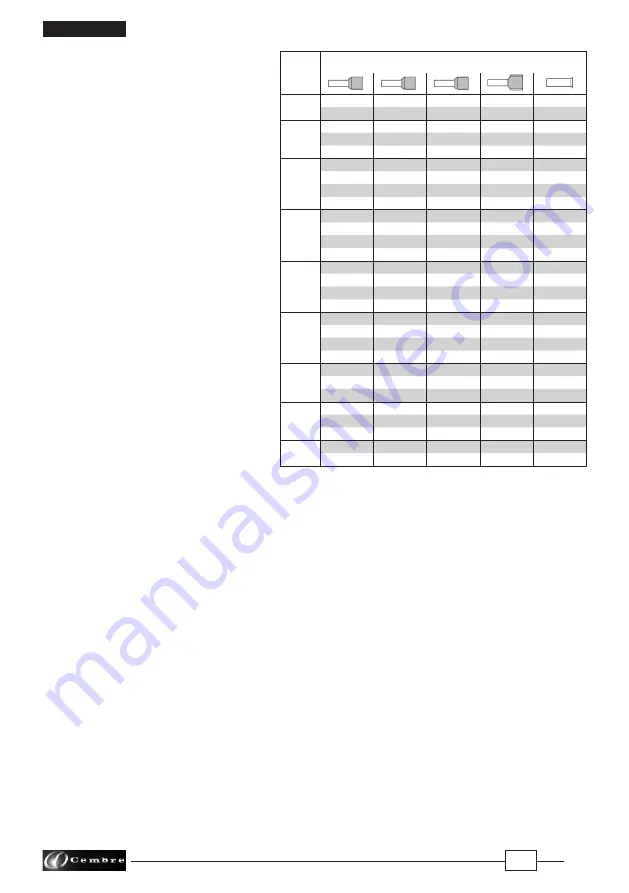

End sleeves types

Die

jaw

Table 1