26

Troubleshooting

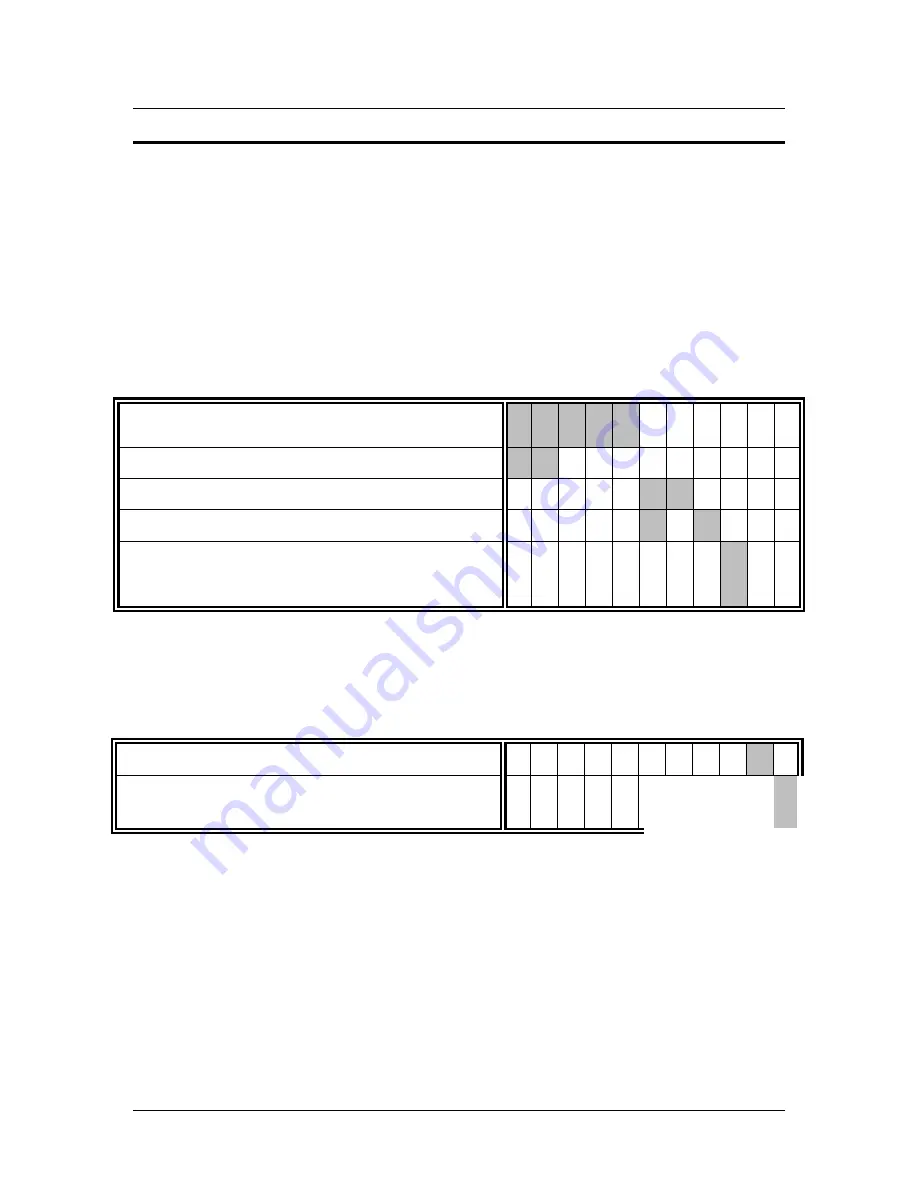

The following table summarizes problems that may be encountered over the life of

CEMLINE

CORPORATION

Electric Water Heaters and Boilers, and the procedures to

remedy those problems. The left-hand column lists the symptoms. The remaining

columns are suggested procedures or "remedies" that should be followed to identify and

correct the problem. If a "

ü

ü

" appears in a remedy column, the corresponding

procedure(s) should be followed to identify and correct the problem.

Electric Water Heaters and Boilers

Symptom

Probable Cause and Remedy #

1

2

3

4

5

6

7

8

9 10 11

The unit does not maintain the required temperature

at the rated capacity.

ü

ü

ü

ü

ü

ü

ü

ü

ü

ü

Outlet temperature is too high.

ü

ü

ü

ü

Pressure / temperature relief valve "pops".

ü

ü

ü

ü

The unit does not maintain the design pressure.

ü

ü

ü

ü

A loud banging in the unit or primary piping (not to

be confused with a normal clicking noise made

during operation).

ü

ü

Electric Boilers Only

Symptom

Probable Cause and Remedy #

1

2

3

4

5

6

7

8

9 10 11

Feed water level incorrect or inconsistent.

ü

ü

The unit does not maintain the required temperature

at the rated capacity.

ü

ü

Summary of Contents for EHB

Page 41: ...38 ...

Page 62: ...59 9 If no leaks are found follow the startup procedures page 17 to put the unit back on line ...

Page 64: ...61 Appendix A cont d ...

Page 65: ...62 Appendix A cont d ...

Page 68: ...65 ...