22

GB

6.2 Maintenance and inspection table

Interval

Assembly

Action

As required

Outside of filling station

Remove any dirt

Monthly

Container

Visual check for damage

Monthly

Piping system

Check hoses for cracks and porosity,

check fittings for leaks (replace defective parts)

Annually

Filter

Clean

Annually, or more

frequently if needed

KITO

®

flame arrester

elements

Blow out the elements with compressed air.

m

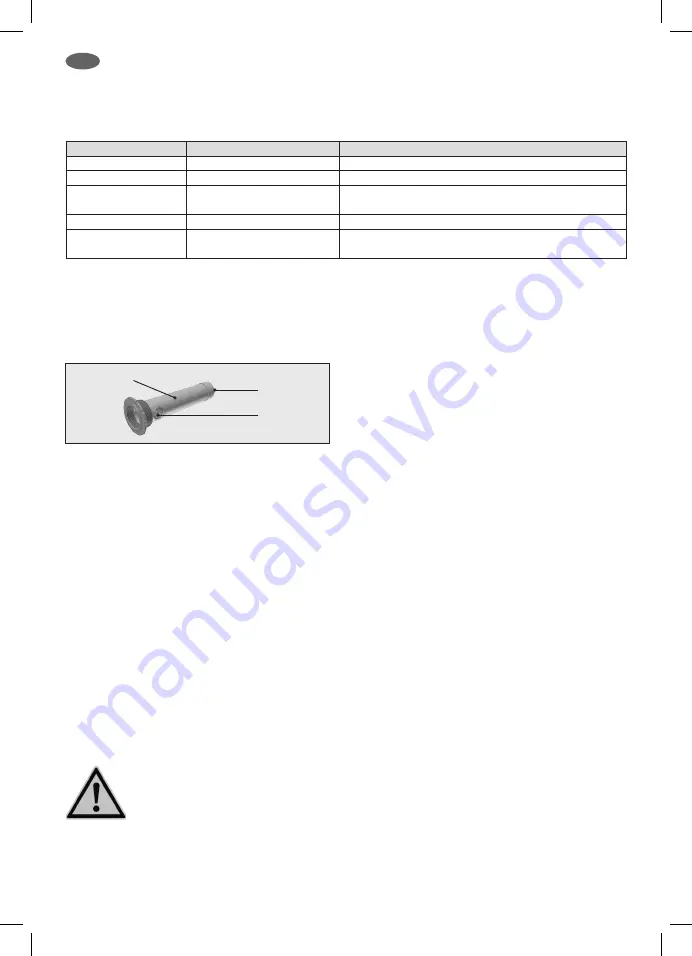

13.1

13.2

Remove anti-twist mechanism

l

.

Remove filling pipe

m

, blow out KITO

®

flame

arrester elements 13.1 and 13.2 with com-

pressed air. Do not, under any circumstances,

remove the flame arrester. Check for damage

caused by corrosion, mechanical loads or

tarnishing, and for loose and slipping strip coils

as a result of flashbacks.

- If there is visible dirt on the elements 13.1

and 13.2 which cannot be blown out, or if they

are damaged, the whole filling pipe

m

must

be replaced as otherwise the filling speed will

be reduced, in which case the flame arrester

function is no longer guaranteed.

If a flashback has occurred, the whole fuel

trolley must be checked and the KITO

®

elements

in the filling pipe replaced.

m

Filling pipe with KITO

®

flame arrester

elements for filling (13.1) and venting (13.2)

7. Decommissioning

the filling station

• First, drain the tank completely (by means of

the pump via the delivery hose and delivery

nozzle while in a horizontal position).

Next:

• Disassemble the petrol trolley into its constitu-

ent parts, sort by material and dispose of in

accordance with local regulations.

Risk

of environmental contamination

through residues in the tank. Collect

these residues separately and dis-

pose of them in compliance with

local environmental regulations.

8. Warranty

Under our general terms and conditions of trade

we warrant that the equipment will be produced

free from defects in materials, functionality or

workmanship.

These can be inspected at

http://www.cemo.de/agb.html

The warranty applies only under the condition

that the above operating and maintenance

instructions and all applicable regulations are

closely followed.

Modification of the filling station by the customer

without consultation with the manufacturer

CEMO GmbH invalidates any claims under the

statutory warranty.

CEMO GmbH also accepts no responsibility for

damage caused by inappropriate use.

Tyre pressure of the transport wheels for the 95 l version 2 bar.

You will find details for cleaning the inlet strainer in the pump

instructions in the chapter “Cleaning the inlet strainer”.

You will find details for troubleshooting pump-related issues in

the pump instructions in the chapter “Troubleshooting”.