16

GB

9. Maintenance and inspection

9.1 Safety measures

i

Important!

The operator must be provided with any protective

clothing that may be required.

Before maintenance and inspection work, turn off the

power supply to the pump.

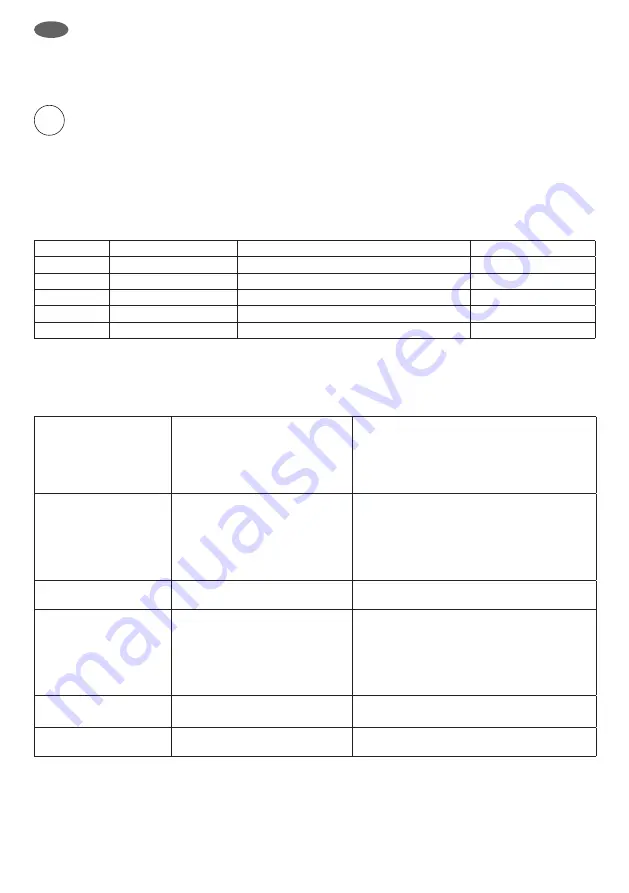

Intervall

Assembly

Action

Carried out by:

As required

Pump exterior

Clean off any stuck on dirt

Operating personnel

As required

Strainer cap, suction side

Clean

Maintenance personnel

Monthly

Housing

Visual check for damage

Operating personnel

Monthly

Housing

Check for leaking seals and loose connections Operating personnel

Monthly

Electrical equipment

Visual check for damage

Operating personnel

9.2 Maintenance and inspection table

Defective and worn parts must be replaced.

Who can carry out maintenance and inspection work?

Normal maintenance work may be carried out

by operational personnel.

10. Troubleshooting

Problem

Possible cause

Solution

System does not vent

air within 1 minute the

first time it is used

Container is empty

Fill the container.

Strainer cap blocked

Clean strainer cap

Air cannot escape from delivery line

Open pressure side valve

(delivery nozzle/system valve)

Pump motor not turning

although pump is

switched on

No power supply

Check that the terminal clamps are correctly

attached and that there is sufficient battery power.

External power pack defective

Check to see if the power pack is plugged in and

switched on and the output voltage is present.

Defective fuse

Check the blade fuse in the black holder

on the connection cable. Replace if nec.

Motor running slow

Insufficient power supply

Provide voltage of at least 80 %

of the nominal value

Pump motor turning

but pump not pumping

Counterpressure too high

(bypass open)

Reduce delivery height or use a larger

cable cross-section

Lines/hoses are blocked

Check to see if the delivery hose is kinked or a

valve is closed.

Motor turning in wrong direction

Check that the polarity of the power supply

is correct.

Increased noise

development

Air bubbles in the liquid

Leave the tank to stand for a few minutes.

Container empty

Fill the container

Broken seal

on pump housing

Defective seal

Replace the pump

Summary of Contents for CENTRI SP30

Page 107: ...107 Notizen ...