OILER MECHANISM ADJUSTMENT

The oiler is preset at the factory, and should not need a en on,

but slight adjustment can be made if desired.

Always ensure

adequate lubrica on.

The jet is screwed in to be level with the end of the body.

Tightening clockwise will reduce oil

fl

ow, and unscrewing an

‐

clockwise will increase the oil

fl

ow.

Lubricator performance is visible in the oil container as agita on of

the oil during saw opera on. (bubbles present in the oil) If no

agita on is observed, reset the oiler.

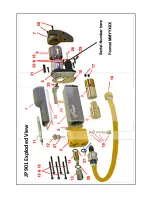

PEDESTAL CLEARANCE WHEN REFITTING

The pedestal, Item 24 (Part No 9344) must always be central to the

bore of the front end. To ensure this, set clearance between the

larger diameter blade grip sec on to be 0.025” (0.64 mm) above

the body.

Check for free movement in the nosepiece, without any hard

contact , which would cause wear and loss of power.

REPLACEMENT OF BLEED TUBE

Fit tube Item 28 (Part No. 93412) and loosely

fi

t two bleed screws

Items 29 (Part No. 5056) Replace the nosepiece, and set one bleed

screw level with the surface.

Set the machine running which will sound and feel uneven, ghten

the second bleed screw slowly un l the tool runs smoothly.

REPLACEMENT OF PISTONS

Eventually the pistons will wear, but oversize pistons can be

fi

ed

at the factory, resul ng is an ‘as new’ performance. This can be

repeated several mes before the bore is worn beyond repair.

Summary of Contents for JP901

Page 1: ......

Page 6: ...JP901 Exploded View ...