16

saue

Axial Piston Pumps, Motors, and Transmissions

Series 70 / 15 Series

General Technical Specifications (Continued)

Allowable Pump Input Shaft Side Loads

The following graphs assume that a self tensioning

device is used to supply tension to the belt, and that

the belt tension is proportional to the amount of torque

required to turn the shaft. Since torque is proportional

to the system pressure generated, belt tension can be

determined by knowing the operating system pres-

sure and the pitch diameter of the sheave.

Typical self tension devices apply five times the

tension to the tight side of the belt as is applied to the

loose side of the belt. The following equations can be

used to calculate the belt side load.

Belt Side Load (lbs.) =

3 x T in

Ds

OR

Belt Side Load (lbs.) =

K x P

Ds

Where:

T in

= Maximum Shaft Input Torque in lbf•in.

Ds

= Sheave Pitch Diameter in inches

P

= System Working Pressure in psi

K

= Constant:

0.33 for BDP-10L or BDU-10L

0.68 for BDU-21L

0.48 for 15 Series

The accompanying graph represents the maximum

allowable conditions based upon shaft stress. All

external shaft loads will have an effect on bearing life.

If continuously applied external loads exceed 25% of

the maximum allowable, contact Sauer-Sundstrand

for unit bearing life evaluation.

Temperature and Cooling

The operating temperature of the transmission should

not exceed 180° F (82° C) continuous and 220° F

(104° C) intermittent. These temperature limits apply

at the hottest point in the transmission, which is

normally the case drain.

Heat exchangers may be installed in the case drain

circuit if necessary, and should be sized to keep the

fluid within recommended temperature limits. Testing

to verify that these temperature limits are not ex-

ceeded is recommended.

Cold oil will generally not affect durability of the

transmission components, but it may affect the ability

to start the engine, flow oil, and transmit power. In

general, cold starts may be made at a temperature

30° F (16° C) above the pour point of the fluid. The

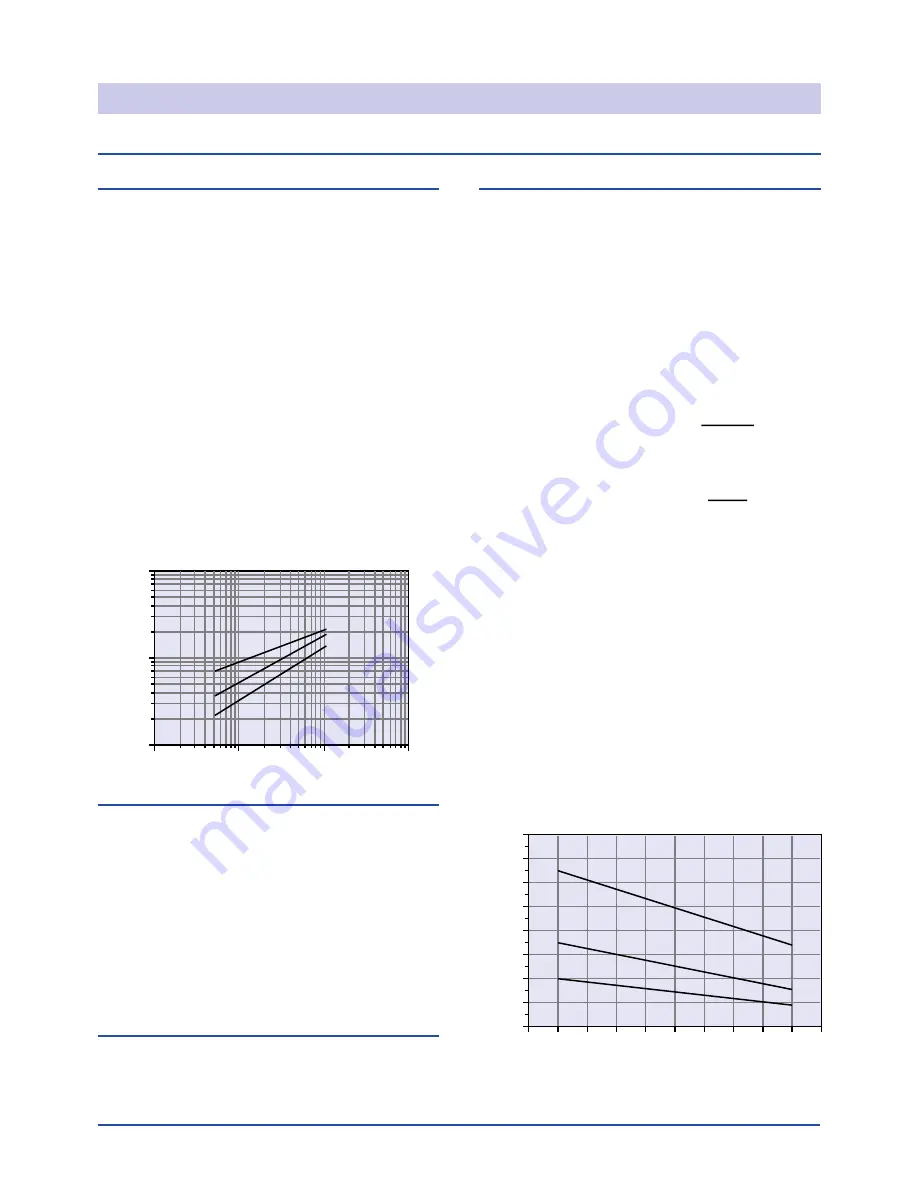

accompanying graph illustrates the relationship be-

tween shaft turning torque at 400 rpm and fluid

viscosity.

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0

100

200

300

400

500

600

700

800

Side Load — lbsf

Distance from Shaft Seal — in

Maximum Allowable Shaft Loads

15 PV

BDU-21L

BDU/P-10

100 000

10 000

1000

100

10

100

1000

Cold Weather Torque to Turn

(@ 400 RPM and 0° Swashplate Angle)

Oil Viscosity - mm

2

/sec

Torque to Turn — lbf•in

15 PV

BDU-21L

BDU-10L

Auxiliary Mounting Pad (15PV)

The 15 Series pump is available with an optional SAE

“A” mounting pad for mounting auxiliary hydraulic

pumps. Since the auxiliary pad operates under case

pressure, an O-ring must be used to seal the auxiliary

pump mounting flange to the pad.

The 9 tooth spline has a 450 lbf•in (51 Nm) continuous

and 950 lbf•in (107 Nm) maximum torque rating.

These ratings assume a 58 Rc hardness on the

mating pump shaft and 0.53 in. (13.5 mm) minimum

spline engagement. The continuous torque rating is

based on spline tooth wear.

Mounting Flange Loads (15PT)

Subjecting 15 Series tandem pumps to high shock

loads may result in excessive loading of the mounting

flange. Studs are provided at the rear of the unit for

attaching a support bracket.

Summary of Contents for 2001 950

Page 2: ......

Page 4: ......

Page 353: ......

Page 413: ......

Page 416: ...saue Axial Piston Pumps Motors and Transmissions Technical Information Series 70 15 Series ...

Page 429: ...14 saue Axial Piston Pumps Motors and Transmissions Series 70 15 Series Notes ...

Page 447: ...31 saue Axial Piston Pumps Motors and Transmissions Series 70 15 Series Notes ...

Page 449: ......