41

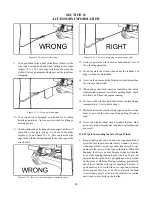

SECTION 11

ACCESSORY INFORMATION

2. Do not allow motor to overheat. Remember, the winch is

only for intermittent use. During long or heavy pulls the

motor will get hot. The internal parts will be hotter than

the case. To check the motor temperature, stop winching

and carefully touch the end of the motor. If the motor

is uncomfortably warm, allow the motor to cool before

continuing — keep the engine running to recharge the

battery during this break.

3. Use a pulley block for heavy loads. To maximize winch

and wire rope life, use a pulley block (Superwinch Part

No. 1503) to double line heavier loads.

4. The pull required to start a load moving is often much

greater than the pull required to keep it moving. Avoid

frequent stopping and starting during a pull.

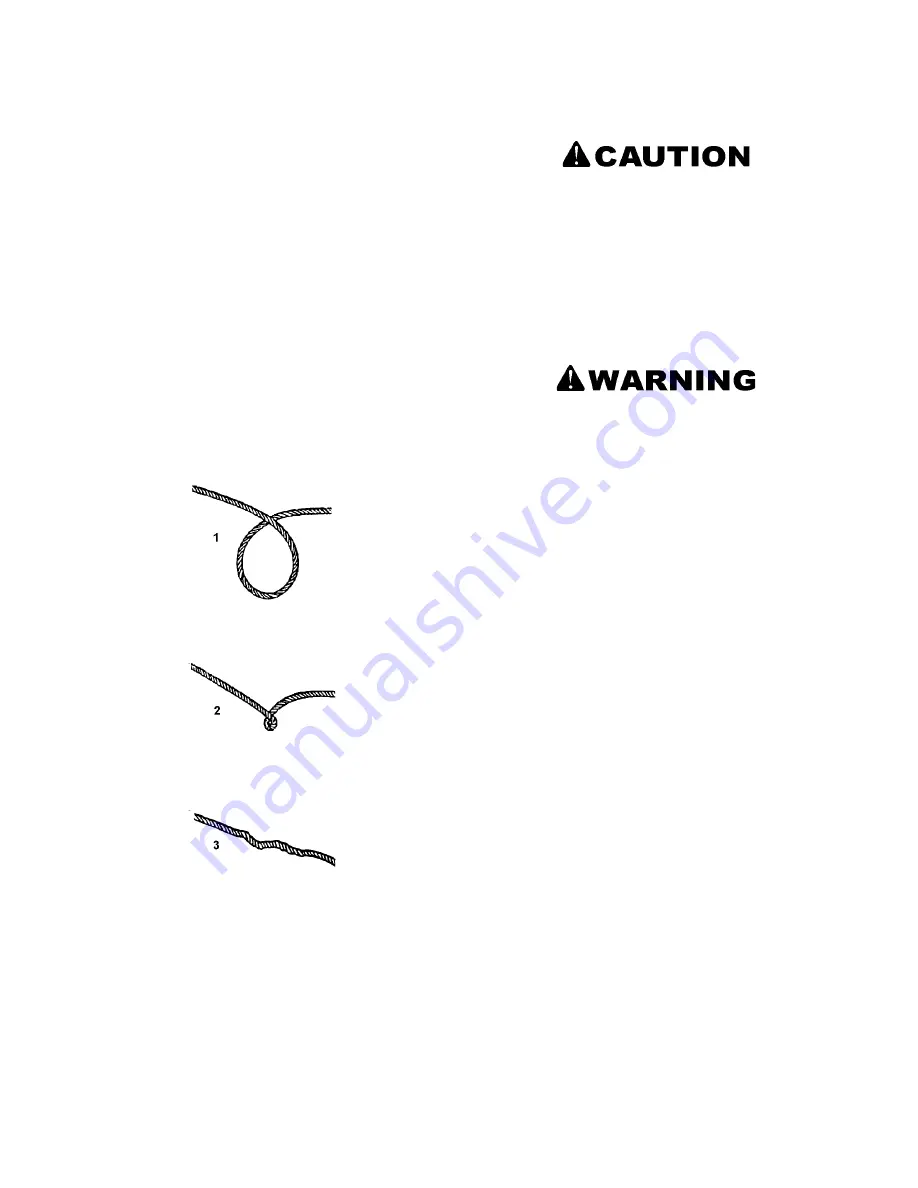

5. Prevent kinks before they occur.

(1) This is the start of a kink. At this time, the wire rope

should be straightened.

(2) The wire rope was pulled and the loop has tightened to

a kink. The wire rope is now permanently damaged and

must be replaced.

(3) The result of kinking is that each strand pulls a different

amount, causing the strands under greatest tension to

break and reduce load capacity of the wire rope. The wire

rope must be replaced.

11.7 RECEIVER WINCH KIT (Part No. 849-123)

The receiver option incorporates a winch brush guard, front

and rear receiver mounting brackets and quick disconnect

cables.

11.8 BILGE PUMP KIT (Part No. 849-146)

The bilge pump kit is recommended when the vehicle will be

used to cross shallow ponds, streams or rivers. The Centaur

utilizes two centrally located pumps to quickly remove water.

It includes a dash mounted switch and wire harness.

The pump is not designed to run dry. Use only when

water has collected in the vehicle.

11.9 SNOW PLOW KIT (Part No. 657-106)

The snow plow assembly attaches to the front mainframe as-

sembly of the Centaur. The plow blade is an 81” (2 m) steel

blade suitable for straight or angled use. The power winch

option is required to raise and lower the snow plow blade.

DO NOT STAND BETWEEN THE PLOW BLADE AND

THE FRONT OF THE CENTAUR. Injury could result if

the blade is raised.

The vehicle operator must observe caution when

operating the vehicle and snow plow in the presence

of others. Injury could result if a bystander is struck

when the vehicle swings to turn or the blade is lowered

onto someone’s foot. Always be aware of the area be

-

ing plowed. Although there is a blade trip mechanism

feature of the blade, damage or operator injury could

result from hitting rocks, stakes or curbs hidden under

the snow being plowed.

11.9.1 Operating Guidelines

1. Do NOT operate the Centaur on open or frozen bodies

of water.

2. For quick removal of the snowplow unit, disconnect the

rear hitch points of the upper boom from the mounting

brackets, unhook and rewind the winch cable.

3. The knives are specially designed to be reversible and

interchangeable with each other once the leading edge

has worn.

11.10 UTILITY TRAILER (Part No. 695-80BL)

The Centaur Four Wheel Utility Trailer has been designed for

use as an additional cargo carrier with any Centaur Off Road

Vehicle.

It is NOT intended for transporting people.

Become familiar with the trailer’s handling characteristics,

especially in hilly conditions, BEFORE using it in unfamiliar

terrain or fully loaded.

The trailer tongue is designed to swivel, much like a universal

joint, even in the roughest terrain.

Summary of Contents for 2008 Centaur

Page 53: ...45 NOTES ...

Page 54: ...46 NOTES ...