CURRENT SENSE OUTPUT TERMINAL 5

This output provides a voltage proportional to the motor current. It is offset from ground

potential by one half of the power supply voltage. The output impedance is 10K ohms.

A clockwise turning motor's current causes the Current Sense Output voltage to become

more positive. A counter-clockwise turning motor's current causes the output voltage to

become more negative.

The transconductance of this stage is variable. It ranges from 0 to 15 volts per amp of motor

current and is adjusted by the Speed Gain Trimpot.

SUMMING NODE TERMINAL 6

This node sums the differential amplifier output, the Current Limit Output, and if connected,

the Current Sense Output.

Connecting the Current Sense Output, Terminal 5, to the Summing Node will make the

CN0121A operate as a speed control.

.

5

If a Phase Compensation Network is

necessary, it may be connected to the

Summing Node, Terminal 6

CURRENT SENSE

6

SUMMING NODE

POWER SUPPLY INPUTS TERMINALS 2 & 10

The power supply is connected to Terminal 2 and Terminal 10. Terminal 2 is the positive

supply input and Terminal 10 is the supply ground.

Reversing the power supply leads to the CN0121A will result in destruction of the drive;

so be careful to check the wiring before powering up the drive.

A regulated supply is recommended but is not necessary. The power supply voltage can

range from 9 VDC to 32 VDC. Do not exceed the CN0121A's maximum rated voltage. The

current rating of the power supply must be at least equal to the maximum motor current plus

the quiescent current draw for the CN0121A. Quiescent current draw (motor not connected)

is 22 milliamps @ 9 VDC to 75 milliamps @ 32 VDC.

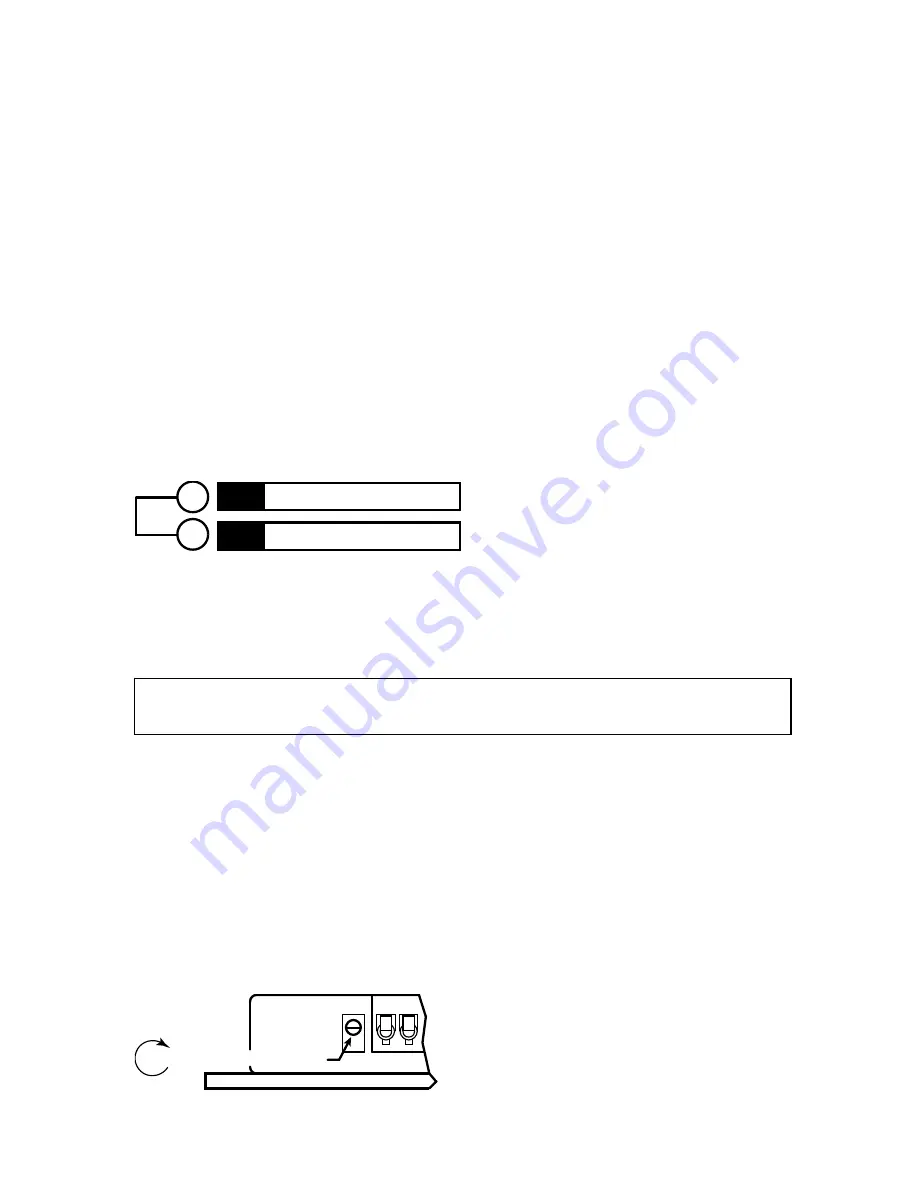

(2) SPEED GAIN TRIMPOT

3

This multi-turn trimmer potentiometer is located on the front face of the CN0121A adjacent

to the Input/Output Connector. Adjusting the Speed Gain Trimpot will offset the motor's

series resistance; thus making motor speed

independent of the torque load. Turn the

trimmer clockwise to increase gain and thus

maintain speed under load. Turn the trimmer

counter-clockwise to decrease gain.

CW INCRESASES GAIN

1 2