56

CLASSIC EDGE OUTDOOR FURNACE • OWNER'S MANUAL

B. FIRE GOES OUT OR KEEPS GOING OUT

1. Wood moisture content is too high - Use properly seasoned wood with a

moisture content of about 25% or less.

2. Diameter of wood too large - Wood between 4" and 8" (10 and 20 cm) in

diameter works well in most cases. Larger diameter wood may need to be split.

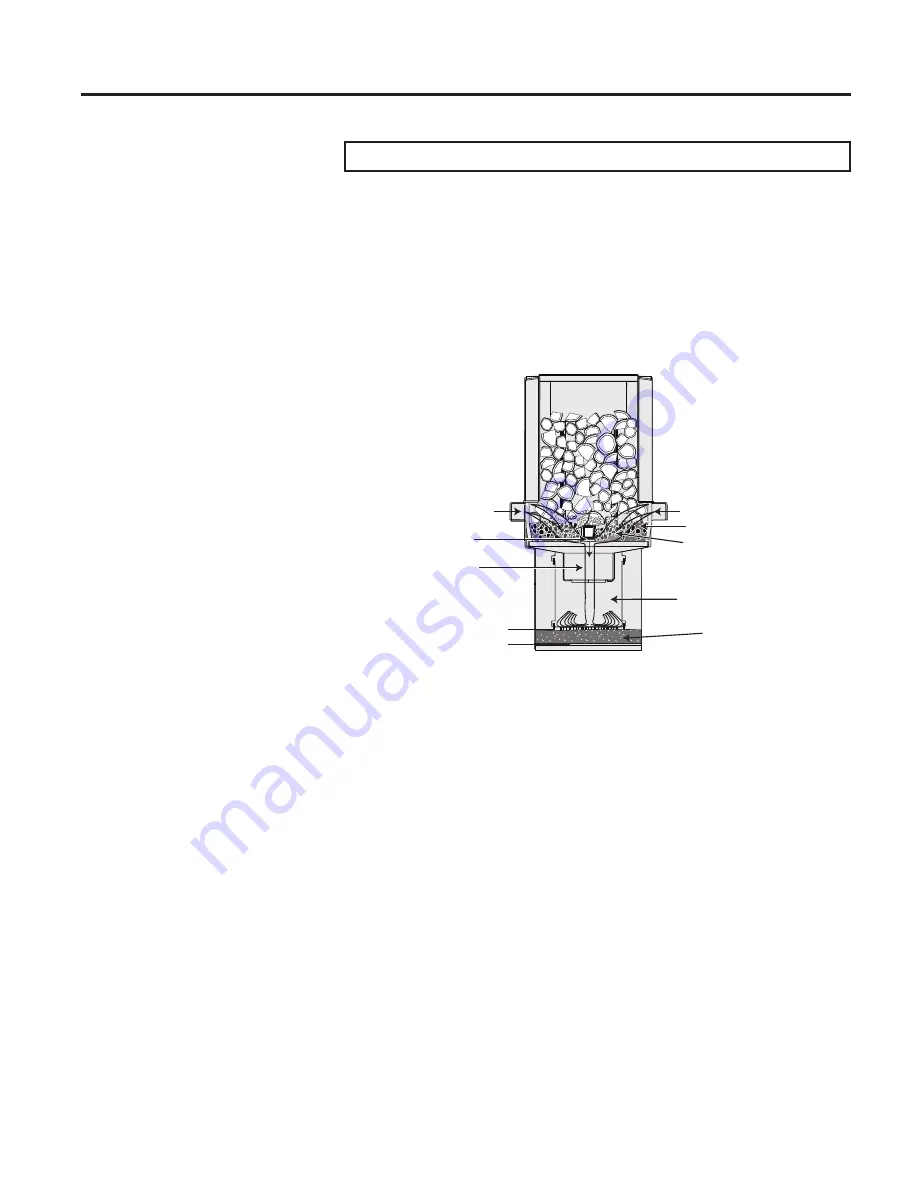

3. Wood too tightly packed - Load the wood so that the combustion air outlets on

the sides of the firebox do not become blocked or restricted.

Flow

Secondary

Air

Mixing

Channel

3" (8 cm) Max.

Coals

Ash

Ash

Reaction

Chamber

Primary

Combustion

Air Outlets

© 2015 Central Boiler

CORRECT

(Proper Flow)

Front View

4. Load of wood too large in relation to coal bed - Adequate coals are needed to

restart the fire after adding wood. If adding too much wood causes the fire to go

out, either add drier, smaller pieces of wood first or partially fill with wood to

allow time for the coals to restart the fire.

5. Water temperature setpoint too low - Set the water temperature setpoint higher

(see FireStar manual).

6. Too much time between idle pulses of air - Reduce the time between idle pulses

of air (see FireStar manual).

7. Length of pulse of air too short - Increase the amount of time the pulse of air is

provided (see FireStar manual).

8. Water temperature differential too large - Set the water temperature differential

to a smaller value (see FireStar manual).

9. Not enough ash in the firebox - Some ash, but not more than three inches, on

the sides and bottom of the firebox is necessary for the proper operation of the

outdoor furnace (as shown in Fig. 46). No ash should cover the mixing channel

(the area alongside the secondary air charge tube). Ash acts as an insulator,

keeping the glowing coals in the bottom of the firebox hot enough to restart the

fire when needed after being in idle mode.