33

NOTE: The combustion air outlets must be visible

(i.e., ash must be kept below the combustion air

outlets as shown in Fig. 39).

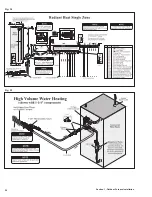

Fig. 37

Combustion

Air Outlets

Gas Ignition

Burner Shield

Secondary Air

Charge Tube

Keep the combustion air outlets open and clear of ash

and coals to allow the furnace to operate properly.

NOTE: Combustion

air outlets are also

located in front

corners.

© 2012 Central Boiler

2. Gasified fuel exits the bottom of the firebox

alongside and under the secondary air charge

tube, through the mixing channel and down to the

Reaction Chamber

™

. Final combustion occurs

in the Reaction Chamber where extremely high

temperatures aid in complete combustion. The

chimney creates a draft (negative pressure) which

helps to draw exhaust gases from the furnace.

3. Heat is transferred to the water from the hot gases

as they move through the firebox, the Reaction

Chamber and the Xtract™ heat exchanger.

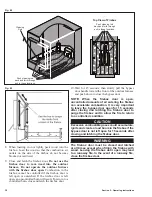

Fig. 38

NOTE: Fig. 38 shows the E-Classic 1450 operating

correctly with proper combustion air flow and

with the wood properly loaded.

NOTE: A key point to remember about the

operation of the E-Classic 1450 is that as wood

burns, the combustion gases flow down through

the bottom of the firebox so the proper flow must

be maintained as shown in Fig. 38.

NOTE: Refer to the General Troubleshooting

Information for more information on outdoor

furnace operation and for conditions to avoid.

Importance of Properly Seasoned Wood

Burning properly seasoned wood (less than 25%

moisture content) will minimize wood usage and

maximize the efficiency and performance of the

E-Classic (see Wood Selection and Preparation in the

Introduction).

In order for wood to burn, the moisture in the wood

must first be evaporated (boiled off). The more moisture

there is in the wood, the more energy it will consume to

dry it and the less energy will be available for heating

the water.

As shown in Fig. 39, the higher the moisture in the

wood, the larger the area in the firebox that is used for

drying and the smaller the area used for burning. This

results in lower efficiency and lower heat output.

The lower the moisture in the wood, the smaller the area

in the firebox that is used for drying and the larger the

area used for burning. This results in higher efficiency

and higher heat output.

Air Flow and Maintaining the Coal Bed

Each time the firebox is loaded with wood, make sure

that air flow through the combustion system is not

blocked or restricted. Maintain 1-3 inches (2.5 cm to

7.5 cm) of loose, glowing coals alongside the charge

tube to optimize the operation of the outdoor furnace. If

the coal bed is too deep, it will restrict air flow and limit

the amount of heat output. If there is no coal bed, or if

the coal bed is too shallow, it will reduce the potential

heat output, and can reduce efficiency.

Generally, the coal bed depth will increase if smaller dry

wood is loaded at more frequent intervals. If too large

pieces of wood and/or wood with too high moisture

content are used, the coal bed is likely to be depleted,

resulting in reduced heat output and efficiency.

Some ash in the bottom of the firebox (but not alongside

the charge tube) is necessary for the proper operation of

the outdoor furnace. Ash acts as an insulator, keeping

the glowing coals in the bottom of the firebox hot

enough to restart the fire when needed after being in

idle mode.

Section 2 - Operating Instructions

Summary of Contents for e-Classic 1450 IR

Page 17: ...15 Section 1 Outdoor Furnace Installation...

Page 29: ...27 Section 1 Outdoor Furnace Installation Fig 30 Fig 31...

Page 30: ...28 Section 1 Outdoor Furnace Installation Fig 32 Fig 33...

Page 66: ...64 E CLASSIC 1450 WIRING DIAGRAM Section 6 General Information...

Page 67: ...65 Section 6 General Information E CLASSIC 1450 WIRING DIAGRAM OPTIONAL POWER IGNITION...

Page 69: ...67 NOTES...

Page 70: ...68 NOTES...

Page 71: ...69 NOTES...