12

Section 1 - Furnace Installation

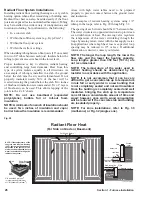

Fig. 8

Gravel or

Small Rock

AUXILIARY BURNER

The auxiliary burner must be installed by a qualified

installer in accordance with local and state and

applicable national codes. Where required by the

authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME CSD-1.

Each optional burner is accompanied by Central Boiler

instructions and the manufacturer's instructions which

provide the information for proper installation, setup,

adjustment and service.

Upon completion of the installation, the entire installation

must be inspected and all safety shutoff devices tested

according to the manufacturer's instructions.

INSTALLING FUEL TANK & GAS PIPING

If installing a fuel tank, it must be installed by a qualified

installer familiar with all regulations and must conform

to the authorities having jurisdiction, or in the absence

of such requirements, with the NFPA 31, the National

Fuel Gas Code ANSI Z223. or CAN/CGA B149.

All gas piping must conform to the authorities having

jurisdiction, or in the absence of such requirements,

with the National Fuel Gas Code ANSI Z223.1 or CAN/

CGA B149. The line should be dug in underground

to the outdoor furnace and supported to the burner

appropriately.

The pipings should be installed and tested for leaks by a

qualified installer familiar with all regulations.

CIRCULATION PUMPS

NOTE: The direction of water flow is very

important for the proper operation of the outdoor

furnace. Installing a swing check valve in the

return line can prevent possible reverse flow.

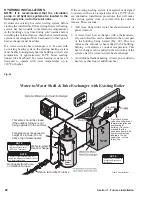

Water Flow

For a single building water-to-air heat exchanger system

with a domestic water heater, the direction of water

flow must go from the hot outlet on the outdoor furnace

to the lower side fitting of the domestic water heater

exchanger, to the lower fitting of the heat exchanger

in the plenum of the existing furnace, and then to the

return port of the outdoor furnace.

NOTE: Some systems may have different flow

patterns.

Access to Ports on Outdoor Furnace

Access to the hot and cold outlets is gained by opening

the control panel on the right-hand side of the outdoor

furnace.

The upper ports are the hot supply outlets and the lower

ports are the return inlets. This configuration allows for

mounting the circulation pumps on the outdoor furnace.

Fig. 9 shows the configuration for proper supply and

return line and pump installations.

NOTE: Pallet Burner outdoor furnaces are

equipped with 1-1/4 inch bungs.

Fig. 9

Installing Circulation Pumps

The Taco 009 is a medium flow, high head pressure

pump that requires an adequate amount of pressure on

the outlet side to prevent the motor from overloading.

The Taco 014 is a high flow, high head pressure pump

that requires an adequate amount of head pressure on

the inlet side to prevent cavitation. Therefore, a Taco

014 may need to be mounted lower near the base of the

furnace, and on the 1-1/4" bung.

The Taco 007 is a medium to high flow, low head

pressure pump. In a very low-resistance system (e.g.,

short length of supply and return lines, only a flat

plate heat exchanger, etc.), the 007 pump may need to

be mounted lower near the base of the furnace or on

the 1-1/4" bung to prevent cavitation at high water

temperatures.

NOTE: See the Hydronic Component Selection

Guide (p/n 2482) for more information.

The following guidelines must be adhered to when

installing the circulation pump(s).