Page 3

Item 97160

For technical questions, please call 1-888-866-5797.

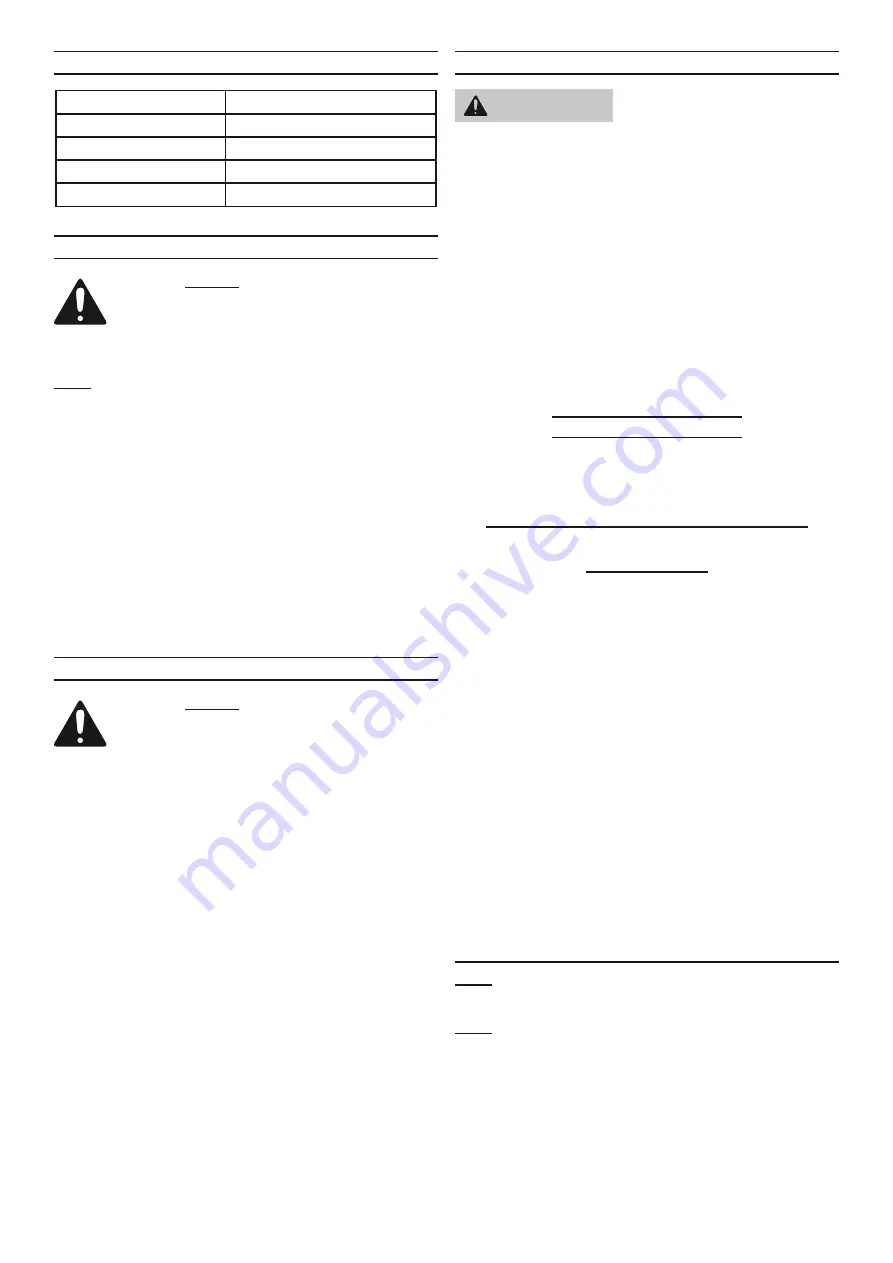

SPECIFICATIONS

Clamp Capacity

Tables up to 1.37 IN. Thick

Adjusts

360° at Base and Jaw

Maximum Jaw Opening

2.25 IN.

Maximum Vise Travel

2.25 IN.

Jaws

2.5 IN. L x 0.59 IN. H

SET UP INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

Note:

For additional information regarding the parts

listed in the following pages, refer to the Assembly

Diagram near the end of this manual.

1.

Connect the Clamp to a work surface.

The work surface must be able to hold the combined

weight of the Vise and intended workpieces.

2.

For heavy duty use or long term installation,

mount the Vise directly to the work surface. Use

the holes in the Vise as a template to mark the

work surface. Verify that installation surface has

no hidden utility lines before drilling or driving

screws. Drill holes and attach the Vise firmly to

the work surface with appropriate hardware.

OPERATING INSTRUCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

1.

Choose the Jaws that are most

appropriate for the job.

2.

Loosen the T-handles and turn the Vise in the

best position for the job. Tighten the T-handles.

3.

Turn the Handle to open the Jaws of the

Vise. Place the workpiece between the Jaws

and close the Vise. The Jaws can damage

soft workpieces, do not overtighten.

4.

Clean, then store the product indoors

out of children’s reach.

MAINTENANCE AND SERVICING

CAUTION

Damaged products can fail, causing personal

injury. Do not use a damaged product. If

abnormal noise or vibration occurs, have the

problem corrected before further use.

1.

BEFORE EACH USE,

inspect the general

condition of the product. Check for loose

screws, misalignment or binding of moving

parts, cracked or broken parts and any other

condition that may affect its safe operation.

2.

AFTER USE,

clean external surfaces

of the product with clean cloth.

3.

Keep the Vise well lubricated. Clean

Jaws to prevent soiling workpieces.

Replacing the Jaws

To replace or attach different jaws. Use a screwdriver

to remove the screws in the face of the jaw.

Attach the new jaws with the same screws.

PLEASE READ THE FOLLOWING

CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR

HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE

TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR

WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO

THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN

FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS

REPLACEMENTS SHOULD BE UNDERTAKEN BY

CERTIFIED AND LICENSED TECHNICIANS, AND NOT

BY THE BUYER. THE BUYER ASSUMES ALL RISK AND

LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT

PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Record

Product’s Serial Number Here:

Note:

If product has no serial number, record

month and year of purchase instead.

Note:

Some parts are listed and shown

for illustration purposes only, and are not

available individually as replacement parts.

Specify UPC 193175412348 when ordering parts.