SKU 65549

For technical questions, please call 1-800-444-3353.

Page 4

pre-operatIonal saFetY.

This product is not a toy. Do not allow chil-

1.

dren to play with or near this item.

Use for intended purpose(s) only.

2.

Inspect before use; do not use if parts are

3.

loose or damaged.

Strut and Spring Compression station should

4.

be securely bolted to the workshop floor

before use.

Apply grease to the front and rear faces of

5.

the main Upright (14) to assist the smooth

sliding of upper and lower strut support (24,

31) Rollers (27).

do not

6.

operate Spring Compressor if parts

are damaged or missing as this may cause

failure and/or personal injury.

Before compressing, make visual inspec-

7.

tion of machine to ensure pins are securely

positioned and that there is no sign of wear

or fatigue. If found, do not use the unit until it

is replaced or repaired by a qualified techni

-

cian.

Ensure upper and lower Shoes (28, 28A),

8.

Strut Supports (31, 24) and their Retaining

Pins (30, 23, 26) are properly positioned.

Their R-Clips (32) and Circlips (29, 22, 25)

must be properly installed.

Before commencing compression of a spring,

9.

ensure ends of the spring are seated and be-

ing held securely in upper and lower Shoes

(28, 28A) of the compressor and cannot slide

out during compression.

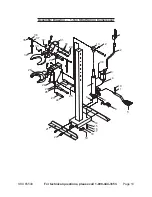

Always fit the Safety Chain (37) around strut

10.

and spring (see Fig. 2). Ensure Chain is not

trapped in the coils of the spring being com-

pressed.

Maintain product labels and nameplates.

11.

These carry important safety information.

If unreadable or missing, contact Harbor

Freight Tools for a replacement.

When compressing the spring, always stand

12.

to one side of the unit.

danGer!

Stop compressing the spring before the

coils touch.

do not

over compress.

Before attempting to remove top cap nut,

13.

always use some type of tool or short stick

to test if the compression has been relieved,

DO NOT use your fingers.

Harbor Freight Tools recommends use of an

14.

appropriate tool, to be supplied by user, to

remove top cap nut from upper strut mount.

Once compressed and strut is removed, it

15.

is a good idea to release the tension on the

spring.

Do not leave the spring under compression

a.

in the machine unattended and do not leave

in compression for prolonged periods, i.e.

overnight.

Before releasing the compression, ensure

16.

that the top cap nut is securely fastened ac-

cording to the manufacturer’s specs.

Release the compression slowly, keeping

17.

your hands and fingers away from the spring

assembly.

Be sure the tension on the spring is fully held

18.

by the strut assembly before removing the

strut from the Shoes (28) of the compressor.

post operatIonal saFetY.

When not in use, clean and store the Spring

1.

Compressor in a safe, dry, childproof location.

Maintain the Spring Compressor in good

2.

condition.

Replace or repair damaged parts. Use

a.

genuine Harbor Freight Tools parts only.

Unauthorized parts may present a hazard

b.

and will invalidate the warranty.

change shoes

Two sets of Shoes (28, 28A), one large

a.

(28A) and one small (28), are provided.

One set handles springs as small as 4" in

diameter and the larger set handles springs

as large as 6.3" in diameter.

To change to the second pair of Shoes, first

b.

undo and remove the Socket Cap Screw

(33) that secures the Upper to the Upper

Strut Support (31). Remove the R-Clip (32).

Support the Shoe with one hand and slide

the Retaining Pin (23) out.

The Circlip (22) will remain in place on the

c.

other end.

Remove the Shoe (28). Hold the alternative

d.

Shoe in place within the support bracket and

slide the Retaining Pin (23) back into place

and lock it with the R-Clip (32). Replace

the Socket Cap Screw (33). The Shoes are