SKU 65549

For technical questions, please call 1-800-444-3353.

Page 5

designed to be used as matched pairs and

should not be mixed.

IntroductIon

The 1-Ton Air/Hydraulic Spring Compressor

1.

is an air actuated hydraulic unit with alterna-

tive foot operation.

asseMblY

The unit requires minimal assembly before

1.

use.

Attach the Angle Steel (21) to the base of

2.

the Upright (14) by using Bolts (20), Nuts

(18) and Washers (19). Be sure Angle Steel

(21) are fixed securely to the base as they

provide stability and will be used to secure

the unit to the floor.

Insert the Foot Pedal (5) into the Socket

3.

(B28) on the hydraulic jack and secure with

the Bolt (10) and Washer (11).

Push Circlips (29) into the groove on each

4.

retaining Pin (30).

Slide the Upper Strut Support (31) over the

5.

Upright (14) to the required height and align

the two holes in the support with two holes

in the Upright. Slide the two Retaining Pins

(30) through the assembly and retain them in

position using the R-clips (32).

Two pairs of shoes (28,28A) are supplied.

6.

Choose one pair of shoes and attach them

to the upper and lower support bracket by

using the socket cap Screw (33), the R-clip

(32), the Retaining Pin (23) and the Circlip

(22). The shoes are designed to be used as

matched pairs and should not be mixed.

The unit must now be fixed securely to the

7.

ground in order to ensure the safety of the

user. Mounting holes are to be found in the

brackets, which allow the unit to be secured

by way of masonry bolts or sinking pins (not

included) into concrete.

WarnInG!

Whichever method is used, ensure the

unit is adequately fixed and cannot topple.

aIr supplY set up

Ensure the Air Valve (1) is in the “Off” posi-

8.

tion before connecting to the air supply. The

Spring Compressor requires 120 PSI to oper-

ate at full capacity.

WarnInG!

9.

Ensure air supply is clean and

does not exceed 120 PSI.

Too high an air pressure and unclean air will

a.

shorten the life of the unit due to excessive

wear, and may be dangerous causing pos-

sible damage and/or personal injury.

Drain the air supply tank daily and clean the

b.

Air Inlet Filter (A16) weekly.

When used, drain air filter at least once a

c.

day.

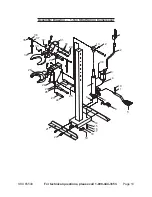

Fig.1

10. For recommended air source and automatic

oiler hook-up, refer to Fig. 1.

Keep hose away from heat, oil and sharp

11.

edges.

Check hoses for wear and make certain that

12.

all connections are secure.

read the entIre IMportant

saFetY InForMatIon section at

the beginning of this document

including all text under

subheadings therein before set up

or use of this product.

saVe tHese

InstructIons.