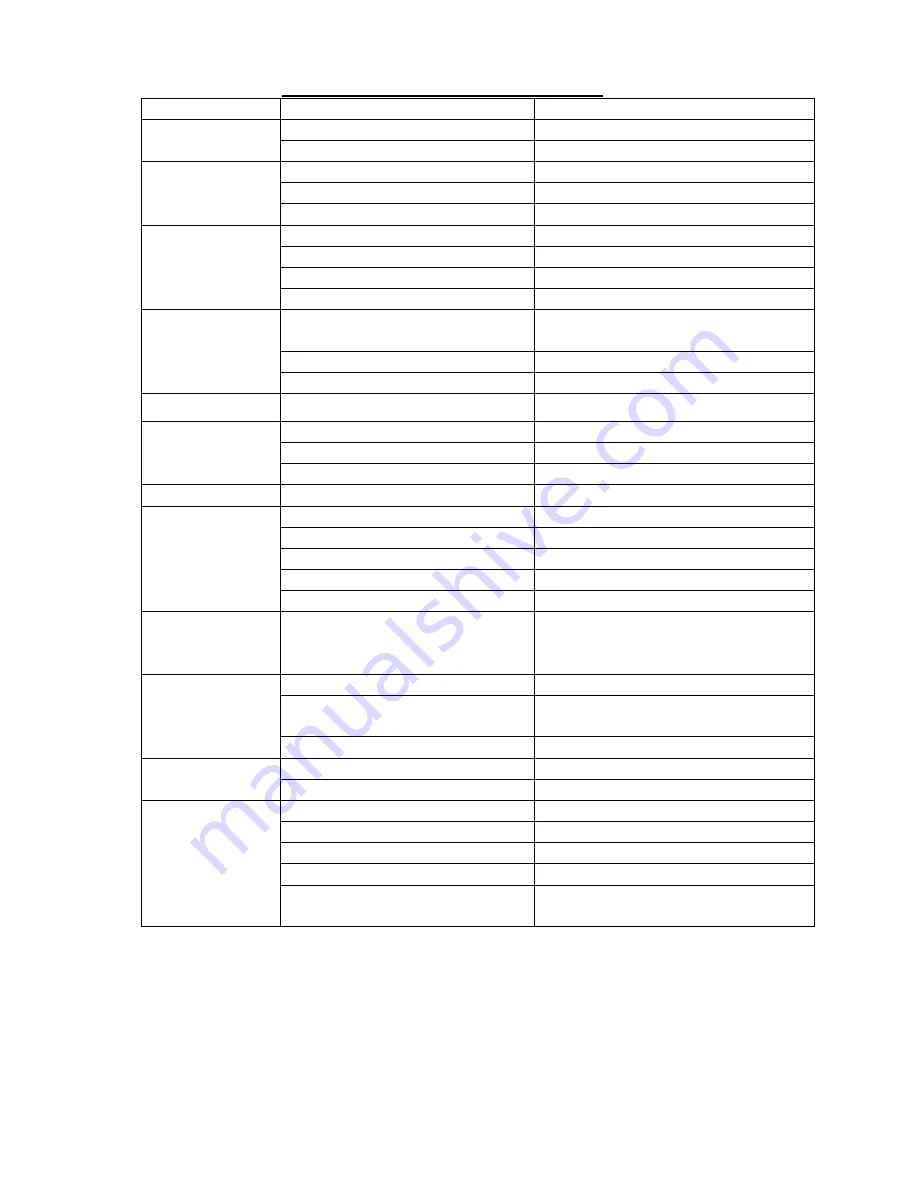

TROUBLE SHOOTING GUIDE

TROUBLE

CAUSE

SOLUTION

1) Synchronization cables out of adjustment

1) Adjust cables to the correct tension (See manual)

Lift going up unlevel

2) Lift is installed on unlevel floor

2) Shim lift to level columns (Do not exceed

½”

)

1) Leak in hydraulic system

1) Find and repair leak

2) Overloading the lift

2) keep load under the rated capacity

Carriages not going

up

3) Problem with pressure relief valve

3) Clean or replace the valve

1) Carriage still engaged in the lock

1) Raise lift up, push lift lowering valve, and lower

2) Lowering valve clogged

2) Check lowering valve in power unit

3) Vehicle not loaded (spotted) correctly

3) Check pickup points for that particular vehicle

Carriages not going

down

4) Foreign object blocking the carriage

4) Remove the object

1) Lock release shaft rusted.

(

Usually occurs on

outside installations or wash bays)

1) Remove covers, oil the mechanism. Operate locks

to allow oil to penetrate

2) Lock release spring broken

2) Replace broken spring

Locking latches do not

engage

3) Lock release cables need adjustment

3) Adjust clamp at cable end

Lift chatters on the

way up

1) Air in the cylinders

1) Bleed cylinders

1) Defect in hydraulic hose

1) Replace hydraulic hose

2) Defect in fitting

2) Tighten fitting, and replace if necessary

Fluid Leak

3) Defect in cylinder packing (seals)

3) Repack seals or replace cylinder if necessary

Fluid is contaminated

1) Water or foreign substance

1) Replace hydraulic fluid

1) Plugged cylinder orifice

1) Remove and clear orifice

2) Lowering valve (screen) clogged

2) Remove and clean valve

3) Wrong weight of fluid

3) Replace with recommended fluid

4) Pinch or restriction in hydraulic hoses

4) Clean and/or replace hydraulic hoses

Slow lowering speed

5) Foreign object in carriage

5) Remove foreign object

Footpads slipping from

pickup point when

raising lift

1) Column not plumb

1) Plumb columns

1) Oversized holes

1) Relocate lift using a new bit to drill holes

2) Concrete floor thickness or PSI strength not

sufficient

2) Tear out old concrete and pour new pads for the

lift

Anchors will not stay

tight

3) Anchors not torqued correctly

3) Torque bolts to the correct spec

1) Overloading the lift

1) Keep load under the rated capacity.

Abnormal noise from

the power unit

2) Hydraulic fluid low

2) Check fluid level, fill and bleed cylinders

1) Defect in motor

1) Replace motor

2) Fuse disconnected

2) Fix fuse

3) Defect in power button

3) Replace button

4) Overhead shut-off cable is activated

4) Deactivate shut-off system

Motor will not work

5) Incoming power voltage is less than 220V

that is needed

5) Have licensed electrician check the wiring