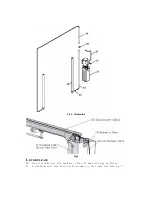

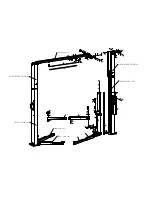

PARTS LIST

NO.

DESCRIPTION

QTY

NO.

DESCRIPTION

QTY

1

POWER COLUMN WELD

1

47

PULLEY AXES

2

IDLER COLUMN WELD

1

48

MIDDLE SPACE SLEEVE

2

2

POWER EXTENSION WELD

1

49

BOLT M8x25

2

IDLER EXTENSION WELD

1

50

STROKE SWITCH

1

3

POWER LOCK COVER

1

51

SHUTOFF BAR CUSHION

1

IDLER LOCK COVER

1

52

SHUTOFF BAR

1

4

SCREW M5x10

8

53

PROTECT CONNECTOR

1

5

BALL HANDLE

1

54

PULLEY FIX HOLDER

1R/1L

6

LOCK RELEASE STUD

1

55A

SADDLE PAD

4

7

NUT M10

1

56C

FLEXIBLE SADDLE

4

8

"C" RING 20

4

58

C RING 28

4

9

LOCK RELEASE WIRE PIN

2

61C

BACK ARM

2

10

LOCK RELEASE SPRING1

2

62C

BACK HOLDER

2

11

LOCK RELEASE SPRING2

2

63

WASHER 10

4

12

LOCK RELEASE SHART

2

64

SPRING WASHER 10

16

13

LOCK RELEASE CONNECTOR

2

65

LOCK SCREW

4

14

BOLT M6

2

66

HOLDER PIN

4

15

SPRING PIN

φ

6x35

2

67

SCREW M10x25

12

16

LOCK PAWL

2

68

GEAR WHEEL

4

17

WASHER

2

69

LIMITED BOLT

4

18

WHEEL AXES

4

70

SPRING PIN 4x24

4

19

WHEEL

4

71

SPRING PIN 4x30

4

20

WASHER 6

8

72

LIMITED SPRING

4

21

SPRING WASHER 6

8

73

LEVEL LIMITED BOLT

4

22

NUT M6

9

74

SLIDE BLOCK

16

23

BOLT

1

75

LIFT ARM

2

24

SPACE SLEEVE

1

76

BUMP SHIELD BLOCK

2

25

BOLT M12x30

28

77

WASHER 8

4

26

WASHER 12

28

78

BOLT M8x30

4

27

SPRING WASHER 12

28

80C

FRONT FLEXIBLE ARM

2

28

NUT M12

28

81C

FRONT FLEXIBLE HOLDER

2

29

LONG HYDRAULIC HOSE

1

82

BOLT M12x45

2

30

TRIANGLE CONNECTOR

1

83

CROSSBEAM JOINTING

1

31

PUMP OUTPUT HYDRAULIC HOSE

1

84

SYNCHRONIZER CABLES

2

32

CYLINDER CONNERCTOR

1

85

NUT M16

6

33

POWER UNIT

1

86

LOCK NUT M8

3

34

SHORT HYDRAULIC HOSE

1

87

SMALL WIRE ROPE

1

35

CYLINDER CONNERCTOR

2

88

NUT M4

2

36

CYLINDER

2

89

WASHER 4

2

37

NUT M8

4

90

SPRING WASHER 4

2

38

BOLT M5x8

10

91

BOLT M4x30

2

39

TUBE CORD BASE

5

92

BOLT M8x20

4

40

BOLT M6x20

4

93

TUBE CORD

1

41

PROTECTIVE BOLT

2

97

LOCK NUT 6

4

42

PROTECTIVE NUT

2

43

R-RING

6

44

WASHER

4

45

SPACE SLEEVE

4

46

PULLEY WHEEL

6