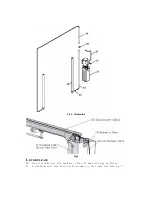

Fig 7 Power Column Lock Idler Column Lock

Release Assembly Release Assembly

THE LOCK RELEASE CABLE ADJUSTMENT IS NOT COMPLETE UNTIL THE LIFT HAS

BEEN LOWERED AND

“

FINAL ADJUSTMENTS

”

HAVE BEEN MADE.

A

RM INSTALLATION

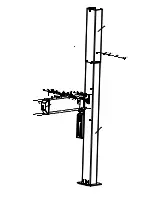

25. Lubricate the arm pin or carriage arm pin hole with

“

anti-seize

”

and install the arms. Insure that the

arm restraint gears engage and disengage properly. Arm restraints any binding occurs, insure that the

large gear mounted to the arm has been factory installed tight against the arm pin.

E

LECTRICAL

26. Connect the Overhead Limit Switch Cord to Power Unit as shown in nameplate on the Power Unit.

27. Connect Power Unit to suitable electrical source as shown in nameplate on the Power Unit.

28.

IMPORTANT

: AFTER WIRING HAS BEEN COMPLETED, TEST OPERATION OF POWER

UNIT & OVERHEAD LIMIT SWITCH. WHILE RAISING LIFT, OPERATE OVERHEAD

SHUTOFF BAR. POWER UNIT MOTOR SHOULD STOP WHEN SHUTOFF BAR IS RAISED.

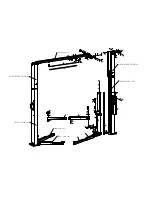

F

INAL ADJUSTMENTS

29.

Lower the lift to the floor and raise the lift approximately one foot.

30.

Start with Idler side first. Slowly and carefully loosen the bleed plug on top of the cylinder just

enough to allow the entrapped air to escape. Repeat for power side.

31.

Energize the power unit and raise 6 inches. Repeat previous step until no air comes out of cylinder.

32.

Pressure test hydraulic system. Energize power unit, raise lift to full rise and continue to run motor

for additional 10 seconds. (NOTE: pressure relief will make a high pitch squeal sound for these 10

seconds.) Check hydraulic system for leaks.

33.

Energize power unit again for 10 seconds. With a clean rag, wipe down both cylinder rods. If

lubricant is not wiped clean from the cylinder rod, the cylinder will appear to be leaking.

34.

Cycle lift to insure that the latches operate simultaneously. Lower the lift onto the locks and insure

that neither lock will wobble (it is possible for the carriages to appear to be resting on the locks

when actually only one carriage is resting on its lock and the other carriage is being supported by

the synchronizing cable).