SKU 39955

For technical questions, please call 1-800-444-3353.

Page 5

Extension Cords

Your tool has a three-prong plug, therefore you must use a three-prong extension cord. Only use rounded

jacket extension cords listed by the Underwriters Laboratories (UL). Improper use of extension cords may

cause inefficient operation of your tool which can result in overheating. Be sure your extension cord is rated to

allow sufficient current flow to the motor.

If you are using the tool outdoors, use an extension cord rated for outdoor use (signified by “WA” on the

jacket).

The extension cord must have a minimum wire size depending on the amperage of the tool and the length of the

extension cord. This size is determined by its AWG (American Wire Gauge) rating. The smaller the gauge, the

greater the cable’s capacity. The amount of cords used does not matter: Total length determines the minimum

AWG rating. Every cord must meet the AWG rating. Use the chart below to determine what AWG rating is required

for your situation. Cord length is rated in feet.

Harbor Freight Tools can supply UL listed and outdoor rated

cords in multiple AWG ratings if needed.

AWG RATING CHART

CORD LENGTH

25’

50’

75’

100’

125’

150’

175’

200’

AMPS

AWG AWG

AWG

AWG

AWG

AWG

AWG

AWG

0-10.0

18

18

16

16

14

14

12

12

10.1-13.0

16

16

14

14

14

12

12

12

13.1-15

14

14

12

12

12

12

12

—-

15-18

14

12

12

12

12

12

—-

—-

D

o

NoT

moDify

your

plug

iN

aNy

way

. i

f

you

have

aNy

DoubT

,

call

a

qualifieD

elecTriciaN

.

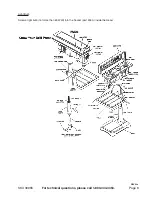

Assembly

Your Drill Press will require assembly. To assist you with assembly and operation please refer to the Assembly

Diagram and Parts List located on pages 14, 15, 16 and 17. Lay out all parts onto a clear section of your

workbench prior to assembly.

Mounting Surface: Ideally, the base should be bolted down prior to the assembly of other components. The

mounting surface must be flat, level and capable of supporting the weight of the Drill combined with the

materials to be drilled.

Before assembling, remove all traces of the packing grease from the Drill Press and wipe all parts thoroughly

with a clean dry cloth. Apply a thin coating of light machine oil to the Table, Column, and Base to prevent rust.

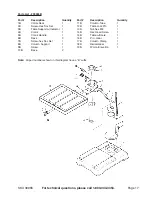

Column Assembly to Base

Step 1)

With the Base (part #10B) on a flat level surface, bolt on the Column Support (part #3B) using

the four (4) M12 Hex Head Screws (part #9B). Tighten Firmly.

Step 2)

Insert the Column (part #11B) into its support and firmly secure this assembly in place with

the Hex Socket grub Screws (part #7B). It may be necessary to unscrew the Hex Socket

Screws (part #7B) slightly to ensure that they do not protrude internally, as this will prevent

the Column from sliding fully into position in the Tube.