SKU 39955

For technical questions, please call 1-800-444-3353.

Page 7

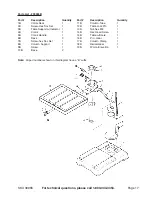

Step 9)

Locate the Column Clamp (part #17B) and insert it into the Table Support. Once inserted,

tighten it by hand. Once this is done, rotate the Worm clockwise with the Crank. If necessary,

loosen the Set Screw in the Crank and reposition the Crank as close to the Table Support as

possible. Tighten the Set Screw.

Step 10)

Check the “gap”, i.e., the clearance between the Table Crank and the Table Support. If the

gap is larger than 1/32”, crank backlash will be minimized.

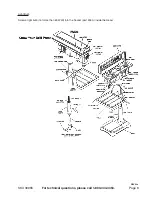

Head to Column

Step 1)

With assistance, slide the Head (part #45A) onto the Column as shown in the Assembly

Diagram. It may be necessary to unscrew the Head Lock Set Screws (part #15A) slightly to

ensure that they do not protrude internally, as this will prevent the head from sliding fully into

position. Align the Head with the Base (#10B) and firmly secure it into position with the Set

Screws. Screw the three (3) Rods (part #19A) firmly into the Hub (part #20A).

Chuck

Step 1)

The Chuck (part #30) is to be assembled to the Spindle (part #32) according to the follow-

ing instructions. Loosely slide the Chuck onto the Spindle. Make certain that the teeth of the

Chuck are not exposed. Put a piece of scrap wood on the table to protect the Chuck nose.

Pull the Spindle down using the Handle. Press the Chuck nose hard against the scrap wood

on the table until the Chuck is forced into a solid fit. The Chuck is pressure fitted.

Pulley Cover Knob

Step 1)

Locate the Knob (part #21) and the pan head screw (part #7). Slide the Knob into the hole in

the front of the Pulley Cover. Twist the screw into the knob from the underside of the Pulley

Cover. Screw on tightly.

Oiler System

Step 1)

Use four M5x0.8-8 Screws (#51A) to fasten the two Oil Brackets (#50A). Insert the Oil Bottle

with Spigot Assembly (#52A and #53A) into the Oil Brackets.