Page 6 SKU # 42976

UNPACKING AND INSTALLATION

1.

Remove protective crating and skids carefully. In the event of damage in transit, contact Harbor Freight

Tools immediately.

2.

The machine is carefully inspected and tested in operation before it leaves the factory. If any

defects are found on delivery, contact us immediately.

3.

Read the owner’s manual and become familiar with the parts and controls on the drawings before

using this machine, as familiarity with the controls will enhance your ability and safety in using it.

ASSEMBLY

1.

After removing the machine from the crate and cleaning it, it must be mounted before use.

2.

This machine can be mounted directly on a worktable, optional Stand (#42977), or floor.

3.

The drill chuck must be installed.

INSTALLATION

1.

It is important that the machine be located on a hard, solid,

level floor, worktable, or optional base, which is capable of

supporting this heavy machine and the workpieces that are

produced. Find a location that supplies easy access to 120

Volt electrical service. Make sure this machine is located in a

well lighted and well ventilated area. The floor should be

resistant to vibration.

2.

Warning: Drill/Mill machines are inherently top heavy.

Before moving the machine, be sure the head is fixed on the

column. Before moving, lower the head as much as possible

to lower the center of gravity. When moving the machine be

careful to keep it balanced; do not allow it to topple over.

3.

To set the machine on a solid concrete foundation, it’s

advisable to apply a little grout to touch up any uneveness in

the concrete in order to get a solid foundation at all points.

4.

When setting machine on a floor or worktable that has any

surface irregularities, shims should be used to correct this

condition to the greatest extent possible.

5.

There are 4 holes in the base for mounting the machine

permanently to a smooth, solid, and level floor,

worktable, or optional stand (#42977).

CLEANING AND LUBRICATION

1.

Thoroughly clean the machine with a commercial degreaser.

Do not use gasoline, kerosene or other flammable liquids.

Avoid getting solvent on rubber parts, or into the electrical

controls or motor.

2.

After cleaning, coat all bright metal with a light lubricant to

prevent corrosion.

3.

Lubricate all gears and moving parts

with a medium

consistency machine oil.

LEVELING THIS MACHINE

1.

Before operation, it is critical to level the work table both lengthwise and crosswise, using a precision

level. It will not be possible to maintain accuracy of machined parts if the mill is not properly leveled.

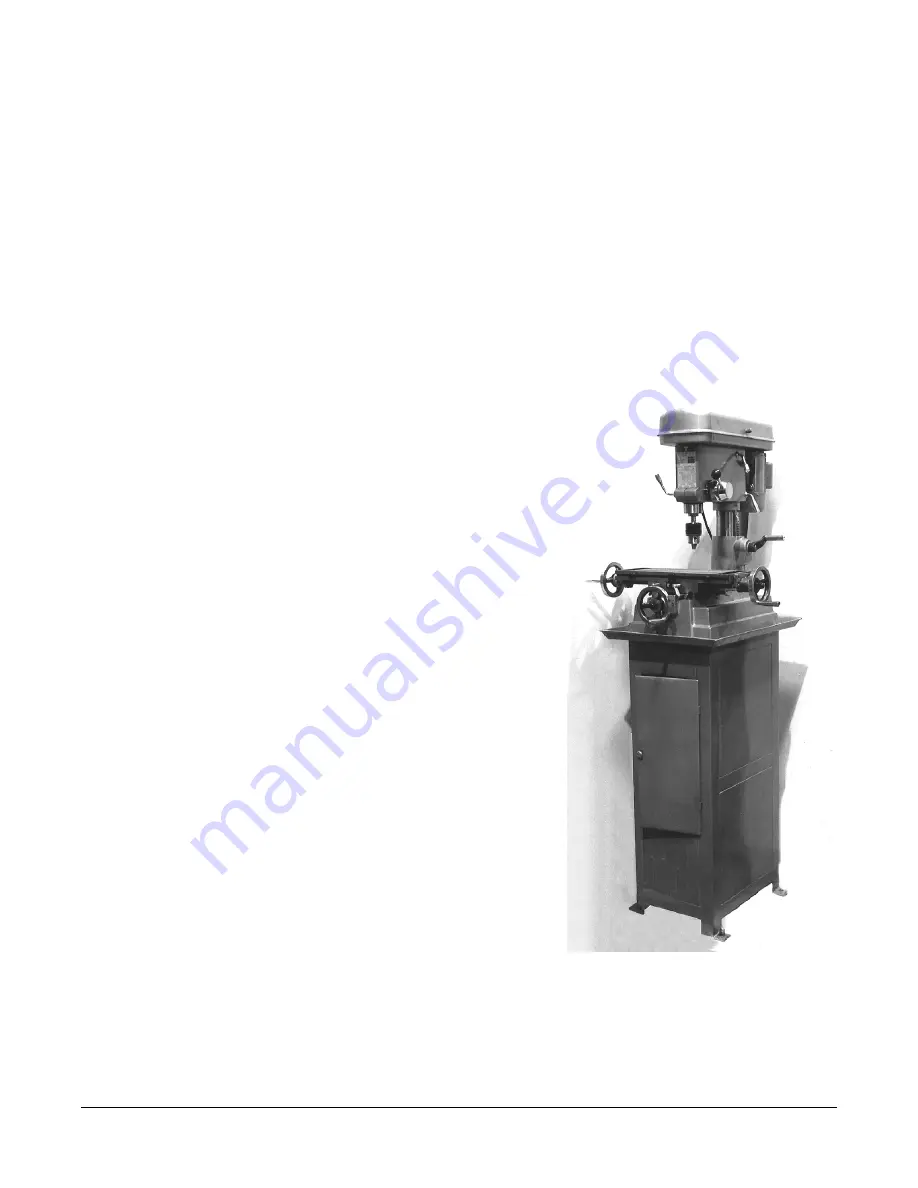

Figure 1. Shown with optional stand.

P/N #42977